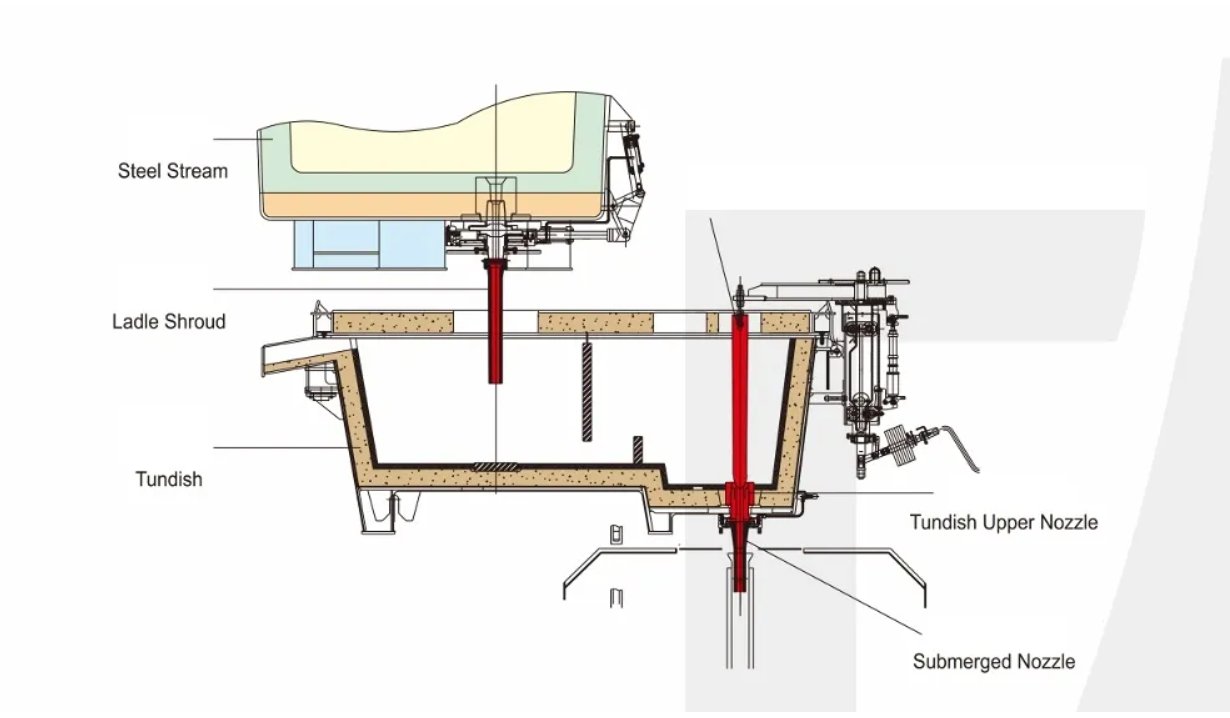

Laurel submerged entry nozzle is one of the core components in the continuous casting process. It is like a "precision navigator" for the flow of molten steel and plays a crucial role in ensuring the smooth and efficient progress of the continuous casting process. Its unique submerged design allows the tip of the nozzle to be directly immersed in the molten steel. This not only effectively prevents the secondary oxidation of the molten steel but also accurately guides the molten steel to flow evenly and stably into the mold, ensuring uniform heat distribution during the solidification of the casting billet and avoiding local overheating or undercooling phenomena. Thus, it improves the quality of the casting billet. Moreover, the shape and size of the submerged entry nozzle can be flexibly customized according to different continuous casting process requirements. Whether it is for producing thin slab, medium-thick slab or special alloy steel billets, it can be perfectly adapted to escort the stable production of high-quality casting billets in the steel industry.