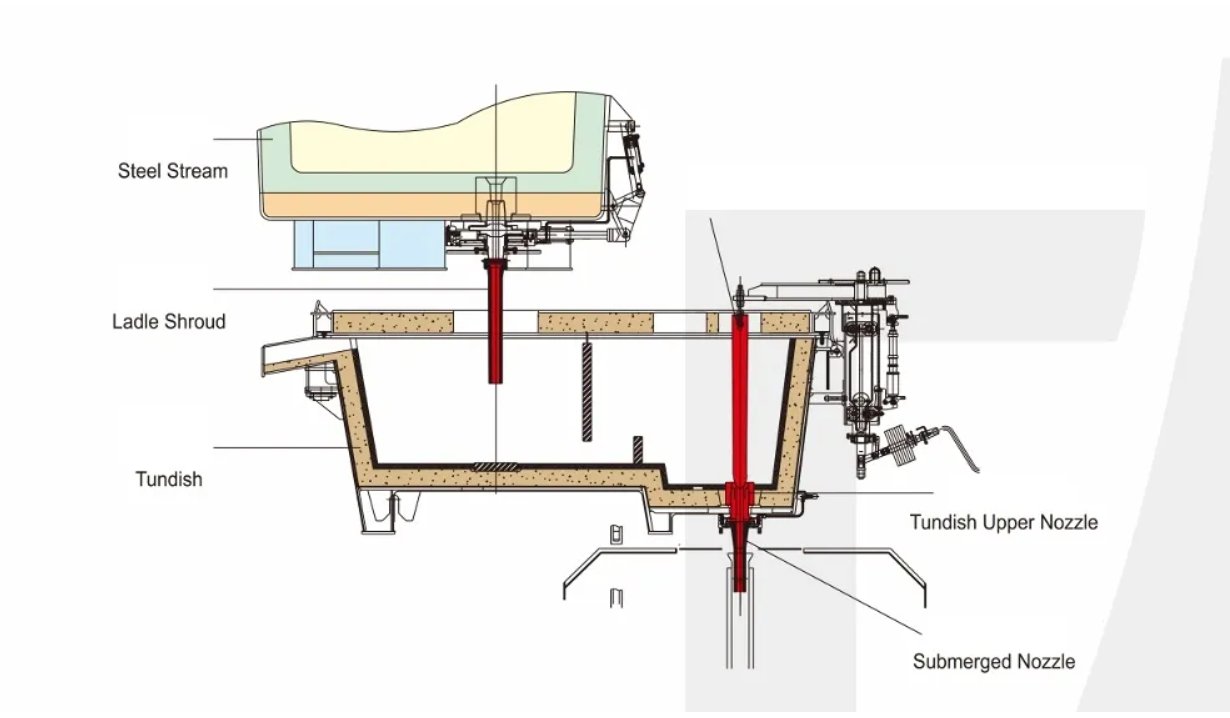

Laurel long nozzle, as an essential and crucial component in the steel continuous casting process, is like a "faithful guardian" for the flow of molten steel, shouldering significant responsibilities. Its slender and elongated design is ingenious. The long tubular structure extends from the bottom of the ladle. When the molten steel is poured, it can minimize the contact area with the air, effectively preventing the secondary oxidation of the molten steel, just like putting a "protective armor" on the molten steel to ensure its purity. Meanwhile, the precisely engineered internal flow channel can guide the molten steel to flow steadily and smoothly towards the tundish, guaranteeing a uniform and stable flow of molten steel. This lays a solid foundation for the precise and efficient implementation of subsequent continuous casting steps, and is of great significance for improving the quality of steel products and optimizing the production process.