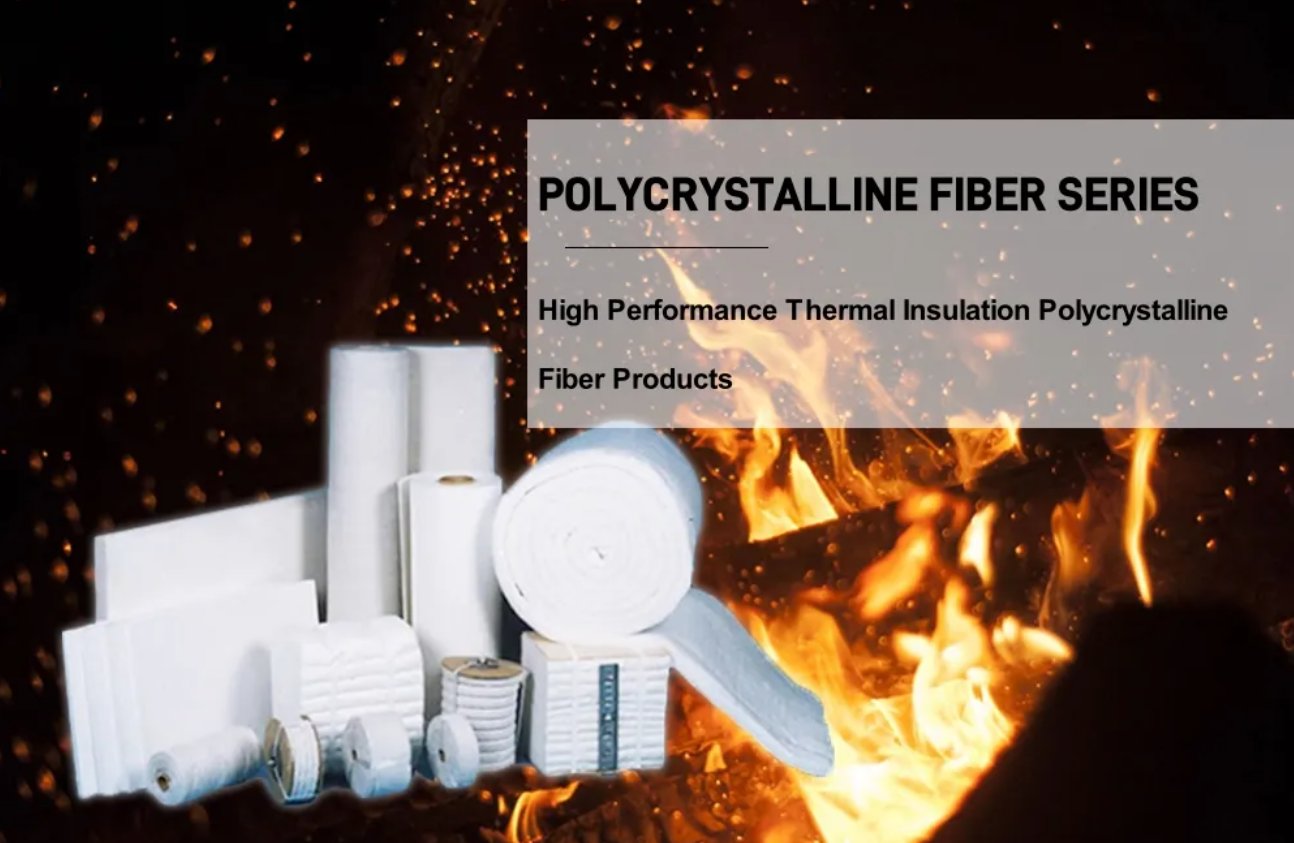

Laurel's polycrystalline mullite fiber board is a premium-grade refractory insulation material made from sol-gel alumina-silica fibers with a polycrystalline microstructure. Manufactured in our advanced polycrystalline fiber board factory, this board features ≥ 70% alumina and is capable of continuous operation at temperatures up to 1600 °C.

These rigid polycrystalline mullite boards deliver outstanding dimensional stability, low thermal conductivity, and excellent chemical resistance. Ideal for high-performance insulation systems in metallurgy, energy, aerospace, and thermal processing sectors.