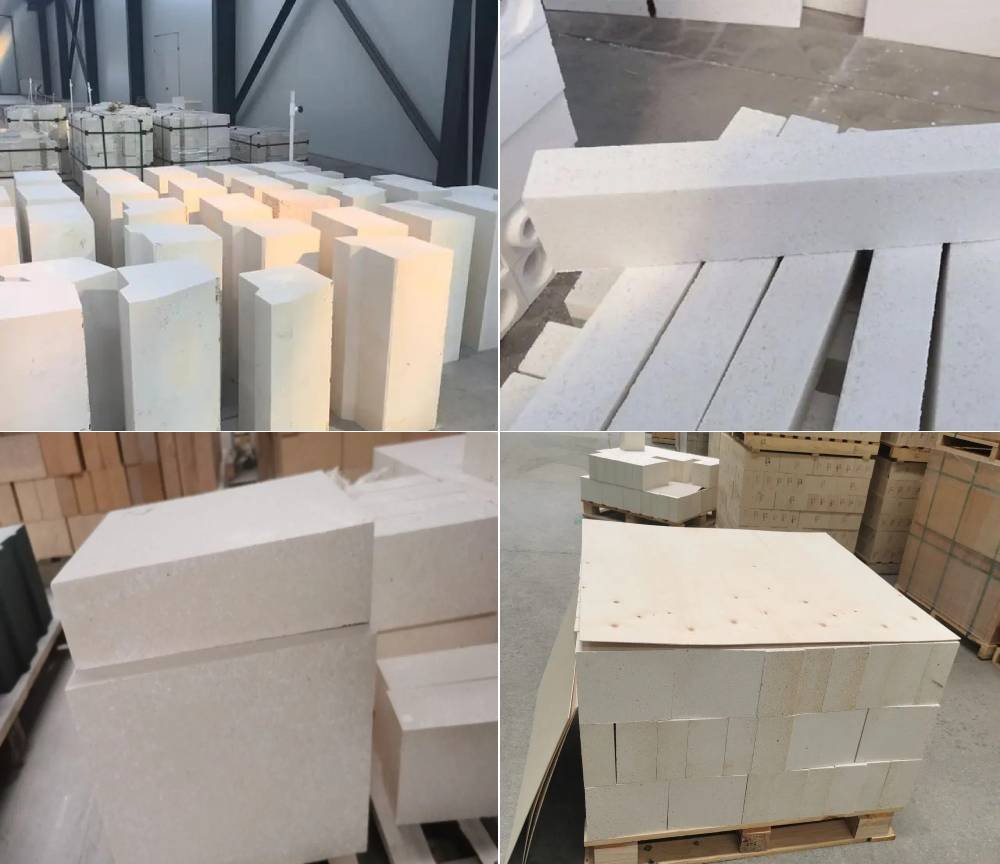

Laurel’s refractory corundum brick series delivers exceptional performance in the most demanding thermal and chemical environments. Produced in our advanced corundum refractory brick factory, these products are made from high purity corundum brick materials—primarily fused α-Al₂O₃—to ensure unmatched structural durability and corrosion resistance.

Ideal for both static and dynamic furnace zones, each high purity corundum brick maintains dimensional integrity and thermal stability under prolonged exposure to temperatures above 1800°C.

From our state-of-the-art corundum refractory brick factory, Laurel delivers high purity corundum brick products that set the standard for refractory corundum brick technology—offering consistent, long-term performance in the harshest thermal processes.