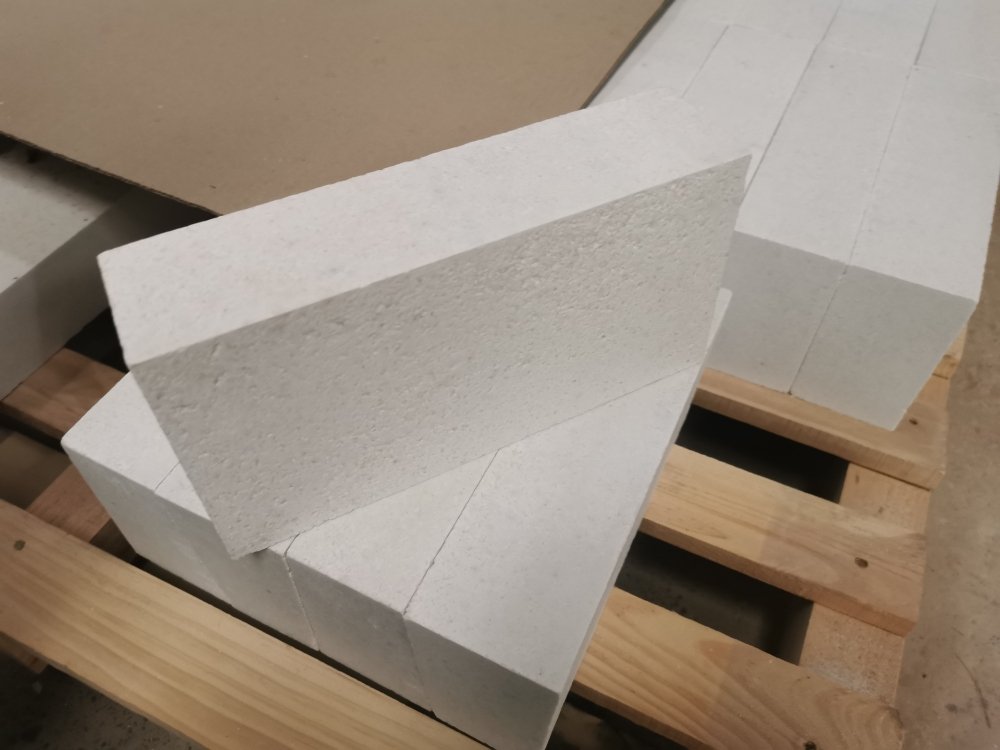

Laurel Mullite bricks are outstanding refractory materials. With mullite as the main component, relying on the high melting point of mullite, they possess excellent high-temperature resistance and can operate stably in a high-temperature environment of 1600℃ - 1700℃. Their dense structure endows them with high mechanical strength, outstanding compressive and flexural capabilities, enabling them to effectively bear heavy pressure and impact. Meanwhile, they also have good thermal shock resistance, being able to maintain their own stability in the face of sudden temperature changes and not prone to cracking or spalling. In addition, they have strong chemical stability and can resist the erosion of most acidic and alkaline slags and molten metals. In high-temperature kilns of numerous industries such as metallurgy, glass, ceramics, and power, they are often used as lining materials to ensure the normal operation and efficient production of the kilns.