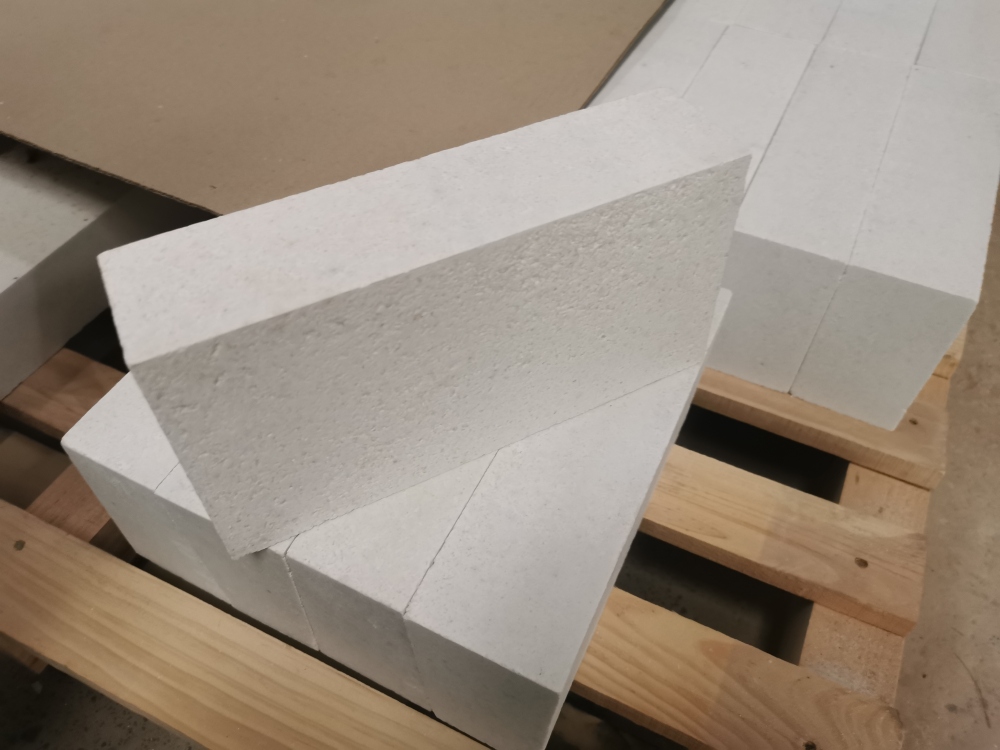

Corundum Brick: High-Performance Refractory for Extreme Industrial Conditions

In modern high-temperature industries, ensuring long-lasting thermal protection and structural integrity is a critical requirement. Among advanced refractory materials, the corundum brick stands out for its remarkable performance in demanding environments. Composed primarily of α-alumina (corundum), this material offers exceptional hardness, chemical stability, and resistance to wear and thermal shock, making it an essential choice for steel, glass, and non-ferrous metal processing industries.

Material Properties and Composition

A corundum brick is made from high-purity bauxite or fused alumina, carefully processed under controlled conditions to form a dense, crystalline structure dominated by corundum grains. This microstructure imparts several key properties:

High refractoriness: Corundum bricks can withstand temperatures exceeding 1750°C without softening or deformation.

Excellent chemical stability: Resistant to acidic and neutral slags, the bricks maintain integrity in aggressive furnace atmospheres.

Mechanical strength: High cold crushing strength allows the brick to support heavy loads in kiln walls and furnace floors.

Thermal shock resistance: The dense, interlocked crystalline structure tolerates rapid heating and cooling cycles without spalling.

These characteristics make the corundum brick ideal for long-term use in areas of high wear and temperature stress.

Industrial Applications

The versatility of corundum brick allows it to serve as a critical component in numerous industrial settings:

Steel and Metallurgy:

Used in blast furnaces, electric arc furnaces (EAF), and ladle linings, corundum brick provides resistance to slag erosion and thermal cycling. Its mechanical strength supports structural stability under the intense weight of molten metal and refractory layers.

Glass Manufacturing:

Glass tank regenerators, port crowns, and hot-face furnace zones incorporate corundum brick to ensure smooth operation at extreme temperatures, preventing contamination and maintaining consistent thermal profiles.

Non-Ferrous Metal Processing:

Copper, aluminum, and nickel smelting furnaces benefit from corundum brick due to its ability to resist metal penetration and maintain dimensional stability, extending lining life and reducing maintenance intervals.

Ceramics and Kilns:

Kiln arches, tunnel kiln floors, and high-temperature firing zones utilize corundum brick to manage thermal stresses while maintaining precise firing temperatures and structural integrity.

Advantages Over Traditional Refractories

Compared to conventional alumina or fireclay bricks, corundum brick delivers several advantages:

Extended service life: Reduced erosion and wear lower the frequency of relining and replacement.

Energy efficiency: Dense bricks retain heat, minimizing furnace heat loss.

Reduced downtime: Strong thermal shock resistance ensures fewer cracks and operational interruptions.

High-load capability: Ideal for heavy-duty industrial furnaces subjected to mechanical and thermal stresses.

These advantages make corundum brick a preferred solution where reliability and long-term performance are paramount.

Customization and Modern Production Techniques

To meet diverse industrial requirements, corundum brick is available in various grades, shapes, and sizes. Advanced production techniques, including high-temperature sintering, precision pressing, and quality control systems, ensure consistent density, thermal performance, and dimensional accuracy.

Manufacturers can produce:

Standard rectangular bricks for conventional furnace lining

Shaped bricks for arches, corners, and special zones

High-density variants for high-wear areas

Magnesia-corundum or spinel-corundum blends for enhanced corrosion resistance

This flexibility allows engineers to design furnace linings optimized for thermal efficiency and structural stability.

Conclusion

With its high temperature resistance, mechanical strength, and chemical stability, corundum brick remains a cornerstone material in modern refractory engineering. Its broad industrial applications, from steelmaking and glass production to non-ferrous metallurgy and ceramics, showcase its versatility and reliability. As production technology advances, corundum brick continues to evolve, offering longer service life, better thermal efficiency, and reduced operational costs for high-temperature industrial processes.

Inquiry Now

Please leave your e-mail and we will contact you as soon as possible

contact us

Your satisfaction is our top priority. Whether you have questions, need support, or want to share feedback, our dedicated team is ready to assist you every step of the way.