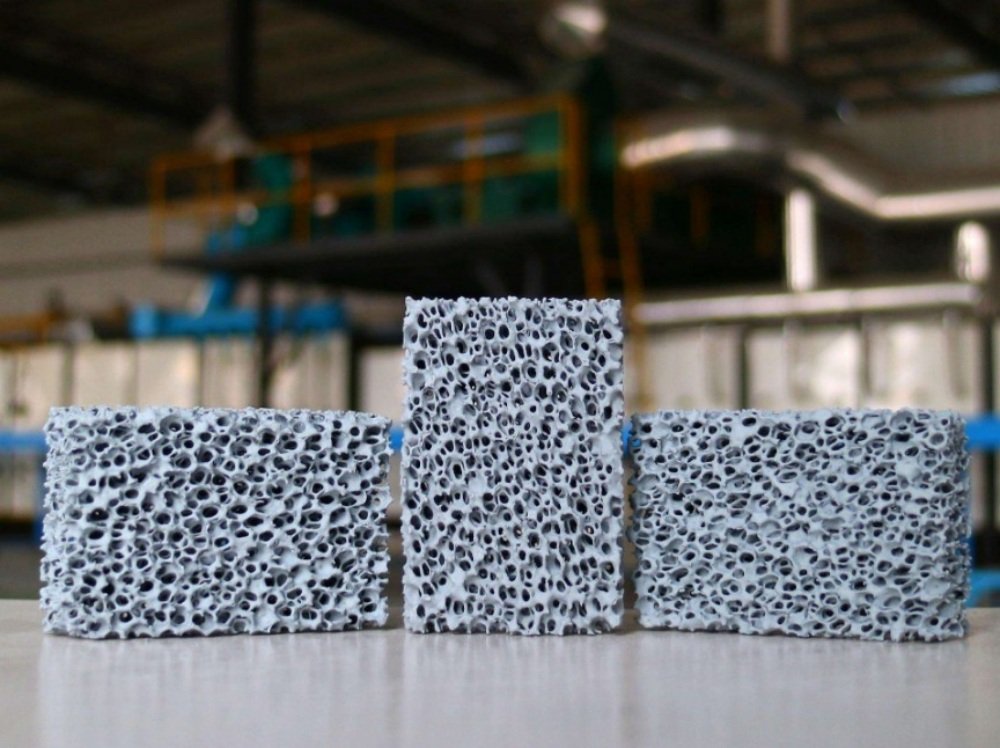

Laurel Ceramic foam filter, as a superior filtering material, is widely used in many key fields. Relying on the unique physical and chemical properties of ceramic materials, they feature excellent high-temperature resistance, suitable for filtering hot fluids in high-temperature industrial environments. With high strength and hardness, they can precisely control porosity and pore size to achieve various filtering precisions, becoming a powerful helper in multiple industries.

Widely used in aluminum, steel, and copper foundries, these filters ensure cleaner castings and reduce inclusions, improving product quality.