Refractory Corundum Brick in Industrial Applications

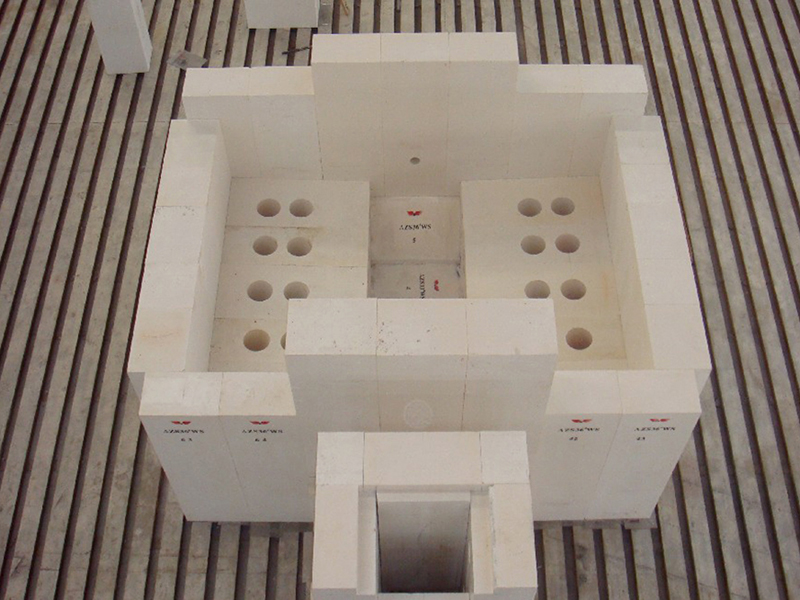

Refractory corundum brick is manufactured from high-purity alumina and refined corundum, shaped and fired at high temperatures. Its dense structure, high melting point, and excellent resistance to aggressive chemical and thermal environments make it one of the most durable refractory products available today.

The typical refractoriness of refractory corundum brick exceeds 1800°C, and its load softening temperature is significantly higher than that of standard alumina-silicate bricks. With a cold crushing strength often above 70 MPa, these bricks maintain their mechanical integrity even in high-load furnace sections where thermal cycling and abrasion are severe.

The dense microstructure of refractory corundum brick provides strong resistance to slag and molten metal penetration. This stability is particularly valuable in furnaces exposed to acidic slags or environments with alternating alkaline and acidic conditions. Chrome or zirconia additions further enhance corrosion resistance, making specific grades of refractory corundum brick suitable for glass tank furnaces and non-ferrous metal smelting.

Unlike some dense refractories that fail under rapid temperature fluctuations, properly engineered refractory corundum brick exhibits controlled thermal expansion and can endure frequent heating and cooling cycles. This feature reduces spalling and extends the campaign life of furnace linings in rotary kilns and electric arc furnaces.

In the iron and steel industry, refractory corundum brick is used in ladle linings, blast furnace hearths, and electric arc furnace roofs. Its resistance to slag corrosion and high load-bearing capacity provide operational stability in long campaigns.

In cement kilns, the transition zone and rotary kiln linings benefit from the abrasion resistance of these bricks, especially under conditions of frequent mechanical impact and dust circulation.

The glass industry relies on zirconia-reinforced corundum bricks for regenerators and furnace bottoms, where molten glass erosion and bubble formation can compromise production quality.

Petrochemical units and incinerators adopt refractory corundum brick for reactors and high-temperature combustion chambers, where resistance to chemical gases and high radiant heat is critical.

Sintered corundum brick, with a fine-grained, dense matrix, provides balance between cost and durability.

Fused corundum brick, produced in electric arc furnaces, offers superior strength and minimal open porosity.

Chrome corundum brick is widely applied in glass furnaces due to its corrosion resistance.

Zirconia corundum brick ensures stability in furnaces exposed to severe chemical attack.

The versatility of refractory corundum brick lies in its ability to serve across industries that demand both structural reliability and resistance to aggressive conditions. Its consistent performance under thermal, chemical, and mechanical stress ensures its continued role as a core material in modern furnace construction.

Inquiry Now

Please leave your e-mail and we will contact you as soon as possible

contact us

Your satisfaction is our top priority. Whether you have questions, need support, or want to share feedback, our dedicated team is ready to assist you every step of the way.