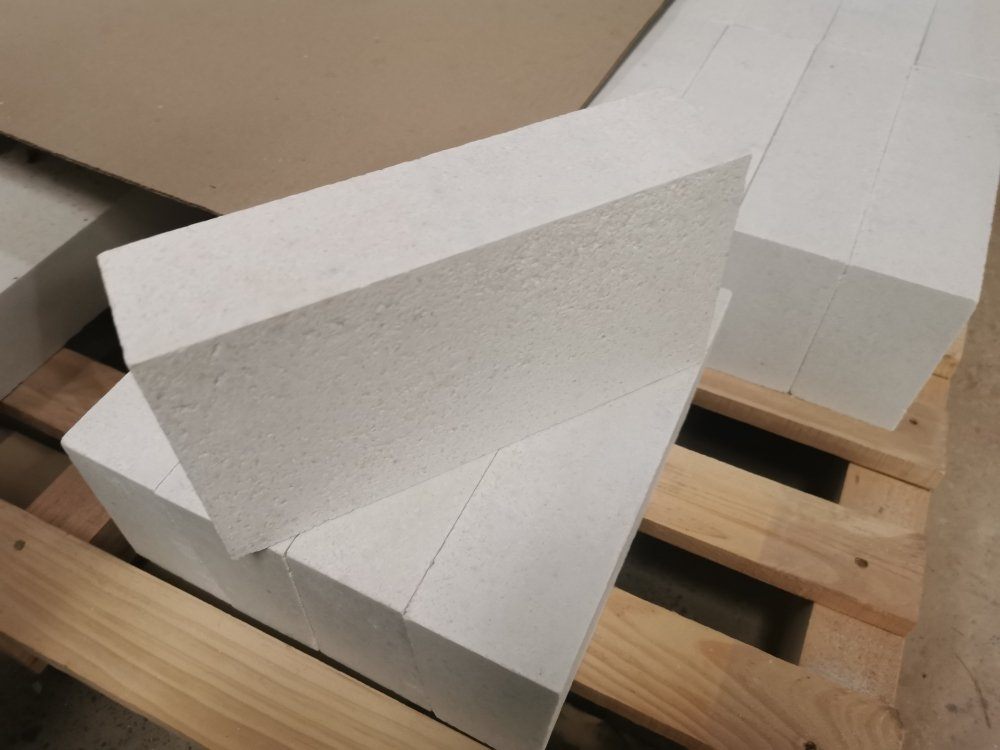

Corundum Bricks: The Ultimate High-Temperature Refractory Solution for Industrial Excellence

In industries where extreme heat, abrasion, and chemical corrosion are constant challenges, Corundum Brick stands out as the premium refractory choice. Engineered for maximum durability, thermal stability, and chemical resistance, this advanced refractory solution is widely trusted for furnaces, kilns, incinerators, and other demanding applications.

If you’re seeking a high-performance lining material, this guide covers the essential advantages, applications, and maintenance tips for Corundum Brick—and why leading industries choose it for operational excellence.

Why Choose Corundum Brick? Core Advantages

Manufactured from premium-grade aluminum oxide (Al₂O₃), Corundum Brick delivers exceptional performance in the harshest thermal environments:

Outstanding Thermal Endurance – Withstands temperatures up to 1800 °C (3272 °F), making it ideal for ultra-high-heat processes.

Superior Mechanical Strength – High compressive strength allows Corundum Brick to resist cracking and deformation under heavy loads.

Excellent Thermal Shock Resistance – Maintains stability through rapid heating and cooling cycles.

Chemical & Slag Corrosion Resistance – Resists acidic and alkaline attacks, extending service life in metallurgy, cement, and glass industries.

Extended Service Life – Reduces downtime and maintenance costs compared to standard refractory products.

Technical Index

Item | Data | |||||

GY99A | GY99B | GY98 | GY95 | |||

Al2O3 | % | ≥99 | ≥99 | ≥98 | ≥95 | |

SiO2 | % | ≤0.15 | ≤0.2 | ≤0.5 | ≤0.5 | |

Fe2O3 | % | ≤0.1 | ≤0.15 | ≤0.2 | ≤0.3 | |

Apparent Porosity | % | ≤19 | ≤19 | ≤19 | ≤20 | |

Bulk Density | g/cm3 | ≥3.20 | ≥3.15 | ≥3.15 | ≥3.1 | |

Cold Crushing Strength | MPa | ≥90 | ≥85 | ≥83 | ≥80 | |

Refractoriness Under Load (0.2MPa) | ℃ | ≥1700 | ||||

PLC (1500℃×2h) | % | ±0.2 | ±0.3 | |||

Key Applications of Corundum Brick

Steel & Metallurgy – Blast furnaces, ladles, electric arc furnaces. Corundum Brick protects against molten metal and slag erosion.

Petrochemical & Refining – Cracking furnaces, reformers, incinerators. Resists corrosive gases and thermal shock.

Cement & Lime Kilns – Burning and transition zones. Handles extreme abrasion and clinker build-up.

Glass Manufacturing – Tank furnaces and regenerators. Prevents contamination in high-silica environments.

Power Generation & Waste Incineration – Boilers, chimneys, thermal reactors. Maintains long-term thermal insulation.

Installation & Maintenance Best Practices

Pre-Installation – Inspect each Corundum Brick for cracks; store in dry conditions.

Laying – Use high-temperature mortar and follow expansion gap guidelines (3–5 mm).

Curing & Heating – Gradually heat to avoid thermal shock; follow proper annealing schedules.

Ongoing Maintenance – Inspect regularly; replace damaged Corundum Brick promptly to maintain performance.

Our Service Promise

We provide more than just Corundum Brick—we deliver end-to-end refractory solutions:

Custom Design – Tailored shapes and sizes for your furnace lining.

Technical Support – Expert guidance on installation and performance optimization.

Fast Global Delivery – Reliable supply for urgent industrial needs.

24/7 Assistance – Immediate support for troubleshooting and emergencies.

Industry Feedback

“Switching to Corundum Brick in our steel plant extended lining life by 40%.”

“Excellent thermal stability in our glass furnace—reduced shutdowns dramatically.”

“Optimized kiln lining with Corundum Brick cut our energy costs by 15%.”

Upgrade your furnace performance with Corundum Brick. Contact us today for technical consultation, free samples, or a tailored refractory solution.

Inquiry Now

Please leave your e-mail and we will contact you as soon as possible

contact us

Your satisfaction is our top priority. Whether you have questions, need support, or want to share feedback, our dedicated team is ready to assist you every step of the way.