Analysis of the Comprehensive Application Advantages of Ceramic Fiber Boards in Modern Industrial Kiln Linings

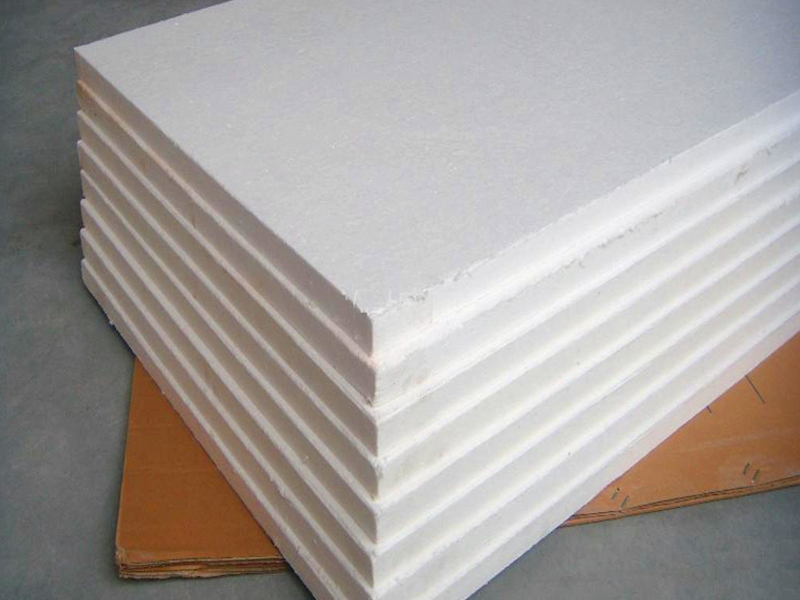

Ceramic fiber boards, as a new generation of high-efficiency refractory and thermal insulation materials, are being widely used in the lining systems of various industrial kilns and thermal equipment. With the development of industrial equipment towards energy efficiency, high efficiency, and intelligence, this material, with its comprehensive performance advantages such as lightweight, low heat capacity, high thermal insulation, and convenient construction, demonstrates significant advantages in optimizing furnace lining structure and controlling operating costs, gradually becoming an important alternative to traditional refractory bricks and castables.

The lightweight and thermal insulation properties of ceramic fiber boards are the core foundation for their application in kiln linings. Compared with traditional refractory bricks, their bulk density is only about one-fifth to one-seventh, significantly reducing the weight of the furnace body and the load on the steel structure, which helps reduce foundation investment and improve equipment structural safety. At the same time, ceramic fiber boards, relying on their porous fiber structure, have a very low thermal conductivity, effectively suppressing heat conduction under both normal and high-temperature conditions, significantly reducing heat loss from the furnace body and providing technical support for the continuous and stable energy-saving operation of industrial kilns.

The high-temperature stability and low heat capacity characteristics of ceramic fiber boards further improve equipment operating efficiency. Depending on the raw materials and processes, the product can cover a long-term operating temperature range of 600℃ to 1400℃ and above, maintaining structural integrity in high-temperature environments without powdering or melting. Its low specific heat and low heat capacity significantly reduce the heat storage of the furnace lining, not only effectively reducing energy consumption during kiln start-up and shutdown, but also significantly accelerating heating and cooling speeds, making it particularly suitable for intermittent operation and industrial scenarios requiring frequent temperature control.

The advantages of ceramic fiber boards in terms of thermal shock resistance, construction, and service life are also outstanding. The internal fiber structure of the material has good flexibility, which can absorb thermal stress generated by rapid cooling and heating. Under frequent temperature fluctuations, it is less prone to cracking and spalling, thus extending the overall service life of the furnace lining. In terms of construction, the boards have uniform specifications, are easy to cut and process, and can be quickly installed using bonding or mechanical anchoring methods. After construction, they can be put into use without complex furnace drying, effectively shortening the project construction cycle and commissioning time.

The environmental adaptability and functional expandability of ceramic fiber boards further broaden their application scope. Except for a few highly corrosive media, this material exhibits excellent resistance to most acids, bases, steam, and industrial furnace atmospheres, and can be used in various hot-face or back-up insulation structures. Its porous fiber structure also provides sound absorption and insulation capabilities, helping to reduce equipment operating noise and improve the working environment in industrial settings. The low thermal inertia characteristic allows the furnace body to respond more quickly to temperature control system commands, creating favorable conditions for precise temperature control and automated operation.

The overall economic value of ceramic fiber boards in the industrial furnace field is gradually becoming apparent. By reducing energy consumption, shortening construction cycles, extending maintenance intervals, and improving operating efficiency, this material demonstrates significant advantages in life-cycle cost control. As industrial energy conservation, emission reduction, and high-efficiency production requirements continue to increase, ceramic fiber boards will play a crucial role in more high-temperature equipment and thermal systems, becoming an important component of modern furnace lining design.

Inquiry Now

Please leave your e-mail and we will contact you as soon as possible

contact us

Your satisfaction is our top priority. Whether you have questions, need support, or want to share feedback, our dedicated team is ready to assist you every step of the way.