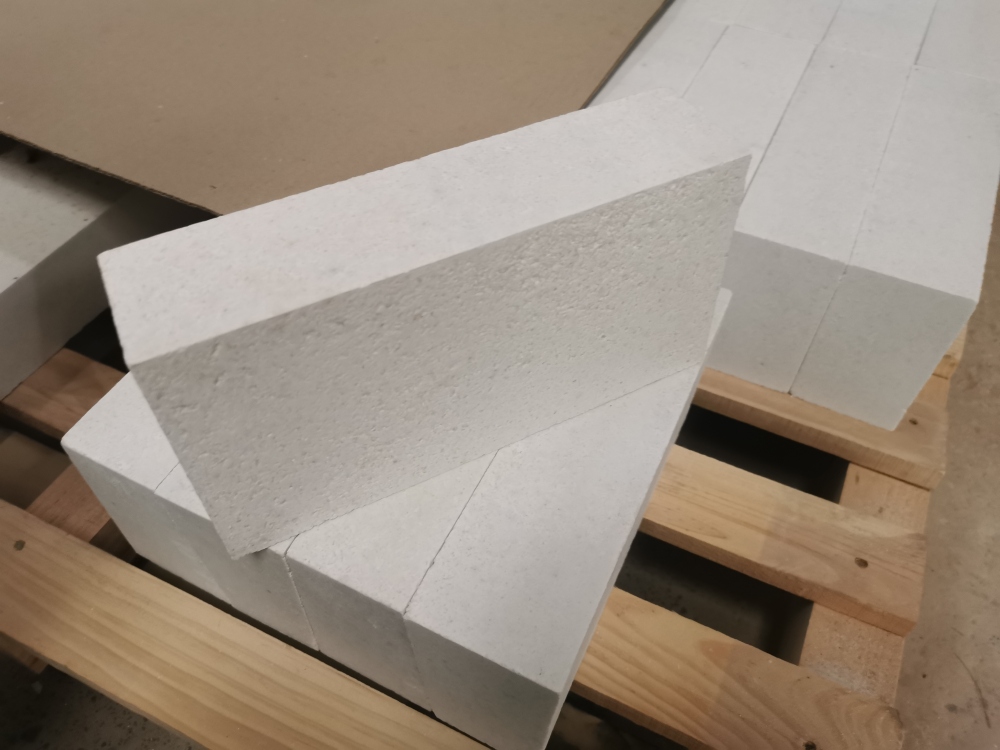

JM/GM Series Mullite Bricks: Precision Insulation for High-Temperature Furnaces

In the field of advanced refractory materials, JM/GM series mullite bricks have become the industry standard for energy-efficient, high-temperature insulation. Known for their low bulk density, high purity, and superior thermal stability, JM/GM series mullite bricks are designed to meet the rigorous demands of modern industrial furnaces, kilns, and heat-treatment equipment.

The JM/GM series mullite bricks are made primarily from high-purity mullite, produced through controlled sintering of synthetic raw materials. Their microstructure consists of evenly distributed mullite crystals, resulting in excellent mechanical strength and dimensional stability even after prolonged exposure to temperatures up to 1800°C. The JM series typically features lighter, more insulating grades, while the GM series offers higher strength and denser formulations for structural applications.

One of the core advantages of JM/GM series mullite bricks lies in their low thermal conductivity. The uniform pore structure minimizes heat transfer, effectively reducing energy consumption and improving furnace thermal efficiency. In continuous or intermittent heating systems, JM/GM series mullite bricks provide stable temperature control and prevent excessive heat loss through the furnace lining.

In industrial applications, JM/GM series mullite bricks are used in a wide range of thermal equipment. They are ideal for hot blast stoves, ceramic kilns, petrochemical furnaces, glass tanks, and laboratory furnaces where insulation and stability are critical. The JM23, JM26, and JM28 grades within the JM/GM series mullite bricks are widely selected for lightweight insulation layers, while denser GM grades are used for working linings or load-bearing zones.

Their chemical stability is another defining feature. JM/GM series mullite bricks resist attack from acidic slags and gases, maintaining their composition in harsh firing atmospheres. They show minimal shrinkage and no deformation after repeated heating and cooling cycles. This makes JM/GM series mullite bricks particularly suitable for long-cycle operations and furnaces that require frequent temperature changes.

Installation of JM/GM series mullite bricks is straightforward due to their precise dimensional tolerance and smooth surface finish. Their compatibility with other insulating materials and refractory linings allows engineers to design layered structures that balance strength, insulation, and cost efficiency.

Beyond performance, JM/GM series mullite bricks contribute significantly to sustainability goals. By lowering energy consumption and extending furnace life, these bricks reduce maintenance downtime and operational costs. Their long service life translates into fewer replacements and lower environmental impact compared to conventional insulation materials.

In high-temperature processing industries, JM/GM series mullite bricks represent a reliable and technically refined solution — a material that combines lightness with strength, insulation with durability. Whether for industrial-scale kilns or specialized laboratory furnaces, JM/GM series mullite bricks deliver consistent thermal protection and operational efficiency, making them an essential component in modern refractory design.

Inquiry Now

Please leave your e-mail and we will contact you as soon as possible

contact us

Your satisfaction is our top priority. Whether you have questions, need support, or want to share feedback, our dedicated team is ready to assist you every step of the way.