Ceramic Fiber Cotton: Flexible and Efficient Thermal Insulation for High-Temperature Applications

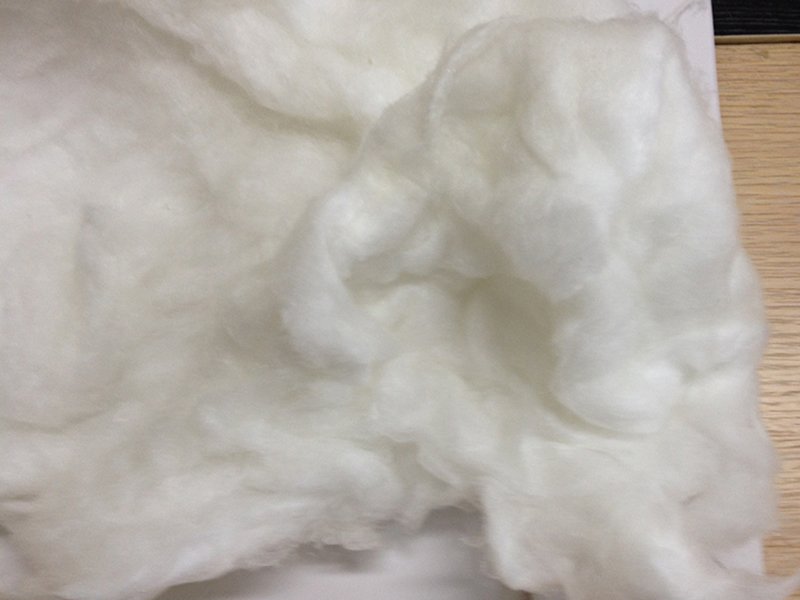

Ceramic fiber cotton is a lightweight, flexible refractory insulation material made from high-purity alumina-silica fibers. It is produced by melting and blowing selected raw materials into fine fibers, forming a soft, uniform, and high-temperature-resistant cotton-like structure. Because of its excellent thermal stability, low thermal conductivity, and resistance to chemical attack, ceramic fiber cotton is one of the most widely used materials for heat insulation and energy conservation in modern industry.

The main advantage of ceramic fiber cotton lies in its outstanding thermal performance. It maintains excellent insulation properties even at continuous service temperatures up to 1260°C or higher. The interlaced fiber network traps air within the structure, minimizing heat transfer and providing consistent temperature resistance across varying thermal conditions. In industrial furnaces, boilers, and kilns, ceramic fiber cotton effectively reduces heat loss and improves overall energy efficiency.

Unlike rigid refractory materials, ceramic fiber cotton is soft, lightweight, and easy to handle. It can be easily shaped, compressed, or filled into irregular spaces without mechanical fixation. This flexibility makes ceramic fiber cotton ideal for sealing, gap filling, and repairing furnace linings. It is also used as the raw material for producing blankets, boards, modules, papers, and other ceramic fiber products, offering versatility in both insulation design and manufacturing.

The chemical stability of ceramic fiber cotton ensures reliable performance in complex environments. It resists most acids, alkalis, and reducing atmospheres, maintaining fiber integrity even under harsh industrial conditions. The material experiences minimal shrinkage during long-term service and exhibits excellent resistance to thermal shock, ensuring durability during repeated heating and cooling cycles.

Applications of ceramic fiber cotton span a wide range of industries. In metallurgy, it is used for furnace lining repair and interlayer insulation in steel and non-ferrous metal smelting. In the petrochemical sector, ceramic fiber cotton serves as a heat-insulating material in reformers, cracking units, and reactors. Power generation plants use it to enhance turbine and boiler insulation, while ceramics and glass industries utilize it to stabilize firing environments and improve product quality.

Our ceramic fiber cotton is available in different grades, such as standard, high-purity, and zirconia-reinforced types, depending on the temperature and chemical requirements of your process. Each batch undergoes strict quality control to ensure consistent fiber diameter, uniform texture, and minimal shot content.

With its combination of light weight, superior heat resistance, and versatility, ceramic fiber cotton remains an essential material for high-temperature insulation. It not only reduces energy consumption but also extends equipment lifespan and enhances production stability — making it a preferred choice for engineers and manufacturers seeking reliable refractory insulation solutions.

Inquiry Now

Please leave your e-mail and we will contact you as soon as possible

contact us

Your satisfaction is our top priority. Whether you have questions, need support, or want to share feedback, our dedicated team is ready to assist you every step of the way.