Calcium Silicate Board: The Next-Generation Solution for High-Performance Thermal Insulation

As global industries move toward higher energy efficiency and stricter safety standards, calcium silicate board has emerged as one of the most reliable and advanced insulation materials for high-temperature systems. Its unique combination of thermal stability, mechanical strength, moisture resistance, and long-term durability makes calcium silicate board a preferred choice across metallurgy, petrochemical processing, power generation, construction, and a wide range of industrial heat-treatment applications. This article provides a deep technical overview of calcium silicate board, explaining its structure, properties, applications, and the reasons why it continues to dominate the insulation materials market.

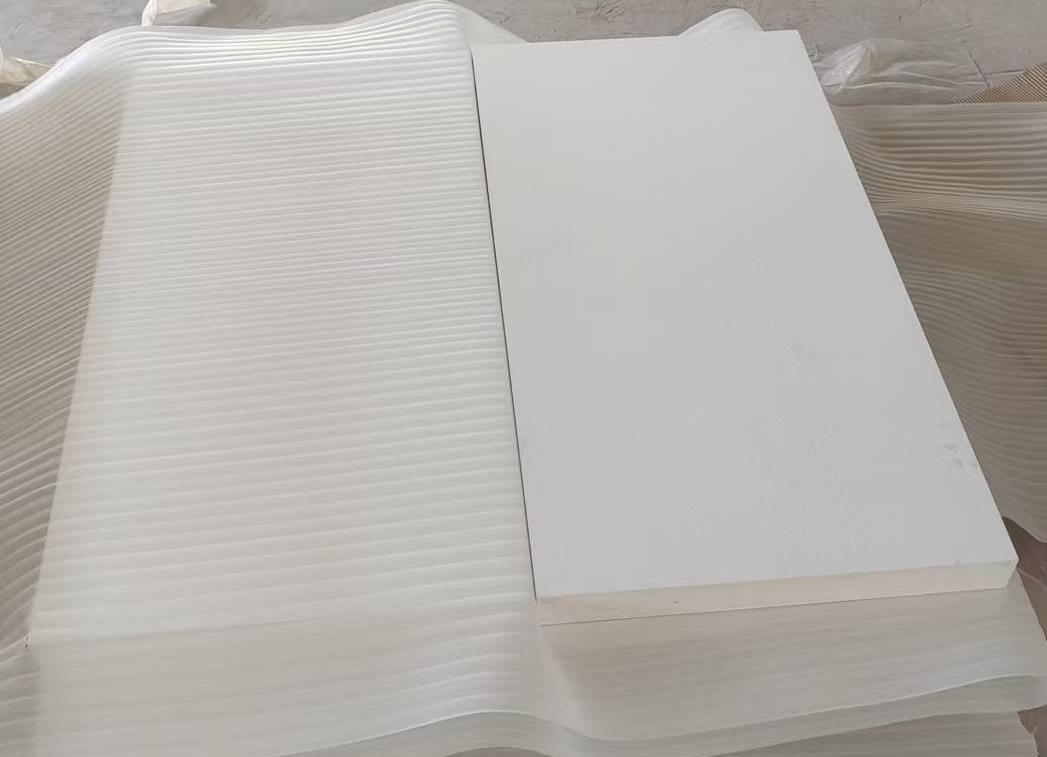

Material Composition and Microstructure of Calcium Silicate Board

At its core, calcium silicate board is produced from a mixture of high-purity lime, silica, reinforcing fibers, and specific additives designed to enhance thermal and mechanical performance. During processing—typically through hydrothermal synthesis or autoclaving—the materials form a robust micro-porous matrix composed of calcium silicate hydrates. These micro-pores are the key to the excellent insulation characteristics of calcium silicate board, allowing it to maintain extremely low thermal conductivity even under continuous exposure to high temperatures.

The stable crystalline structure ensures that calcium silicate board can withstand temperatures of 650°C, 1000°C, or even higher depending on the grade. Unlike traditional insulation materials, calcium silicate board does not shrink, crack, or disintegrate under thermal cycling, which is crucial for long-term reliability in industrial environments.

Mechanical Strength and Load-Bearing Performance

One of the distinguishing advantages of calcium silicate board is its exceptional mechanical strength compared with other lightweight insulation products. It maintains structural integrity under compression, making it suitable for areas subjected to vibration, mechanical stress, and handling abuse. This makes calcium silicate board especially valuable in power plants, refineries, furnaces, and kiln linings where equipment maintenance and thermal shock are frequent.

While many insulation materials collapse when exposed to pressure or thermal cycling, calcium silicate board retains its dimensional stability. This enables engineers to design more secure insulation systems that maintain efficiency over years of service, reducing the risks of hot spots, premature system failures, and excessive energy consumption.

Fireproofing, Moisture Resistance, and Chemical Stability

Modern industrial operations require materials that perform not only under heat, but also under moisture, fire, and chemical exposure. In this regard, calcium silicate board is exceptionally versatile. It is a non-combustible material with excellent fire resistance, often used as a protective layer in structural fireproofing for tunnels, high-rise buildings, and power facilities.

The hydrophobic properties of many advanced grades of calcium silicate board allow it to resist moisture absorption. Even after exposure to water, it dries quickly and regains its original strength and insulation performance. The board’s resistance to most acids, corrosion, and microbial growth further expands its suitability in harsh operating environments such as chemical plants and offshore platforms.

Application Range Across Heavy and Light Industries

The growing global demand for durable and efficient insulation materials has expanded the application scope of calcium silicate board significantly. It is widely used in:

Industrial furnaces and kilns

As a lining material or back-up insulation layer to improve furnace efficiency and reduce heat loss.

Power generation and petrochemical facilities

Calcium silicate board is used in piping systems, boilers, steam chambers, and exhaust ducts due to its strength and reliability.

Construction and fire protection

Its non-combustible nature makes calcium silicate board a key material in fire-rated walls, ceilings, and partition systems.

High-temperature equipment insulation

Including reactors, drying chambers, thermal processing equipment, metallurgy ladles, and heat-treatment systems.

The engineering flexibility of calcium silicate board, combined with its ease of cutting, shaping, and installation, provides manufacturers and contractors with a highly adaptable material suitable for both new builds and retrofits.

Energy Efficiency and Cost Reduction

In an era where energy conservation directly impacts operational budgets, calcium silicate board plays a critical role in reducing energy waste. By minimizing thermal losses, facilities can achieve:

10–20% higher thermal efficiency

Lower fuel consumption

Extended service life of refractory linings

Reduced frequency of shutdowns for maintenance

These benefits translate into significantly lower operating costs. Many industries report that the initial investment in calcium silicate board is recovered within months due to the resulting energy savings and reduced equipment downtime.

Future Trends and Technological Development

As insulation requirements become more stringent, innovation in calcium silicate board continues. Future trends include:

Higher-temperature formulations exceeding 1100°C

Enhanced hydrophobic and anti-corrosion grades

Ultra-lightweight versions for aerospace and new-energy sectors

Boards with improved machinability for advanced equipment design

The global shift toward clean energy, electrification, and industrial automation will further increase the demand for reliable materials such as calcium silicate board. Its multifunctional performance ensures a long-term role in the development of high-performance insulation systems.

Inquiry Now

Please leave your e-mail and we will contact you as soon as possible

contact us

Your satisfaction is our top priority. Whether you have questions, need support, or want to share feedback, our dedicated team is ready to assist you every step of the way.