Refractory Mortar: Essential Bonding Material for High-Temperature Masonry Systems

Refractory mortar is a specialized binding material designed to join refractory bricks and shapes in high-temperature industrial and construction applications. Unlike ordinary cement-based mortars, refractory mortar is formulated to withstand extreme heat, thermal cycling, and chemical attack while maintaining strong adhesion and structural integrity. Refractory mortar plays a critical role in the overall performance of refractory linings, as joint quality directly affects heat resistance, mechanical stability, and service life.

Refractory mortar is typically composed of graded refractory aggregates, high-purity binders, and carefully selected additives. The composition is matched to the type of refractory brick being used, such as fire clay bricks, high alumina bricks, silicon carbide bricks, or corundum bricks. This compatibility ensures similar thermal expansion behavior between the refractory mortar and the bricks, reducing internal stress and minimizing the risk of cracking or joint failure during furnace operation.

One of the most important characteristics of refractory mortar is its high-temperature resistance. Depending on the formulation, refractory mortar can withstand service temperatures ranging from 1300°C to over 1800°C. Even under continuous exposure to intense heat, refractory mortar maintains bonding strength and resists softening, ensuring that the refractory structure remains stable over long operating cycles. This performance is essential in furnaces, kilns, boilers, incinerators, and metallurgical equipment.

Chemical stability is another key advantage of refractory mortar. In industrial environments, refractory linings are often exposed to acidic or alkaline slags, molten metals, flue gases, and corrosive vapors. High-quality refractory mortar is engineered to resist chemical penetration and erosion, protecting joints from premature degradation. This resistance helps maintain a tight, sealed lining that prevents heat loss and protects furnace shells from damage.

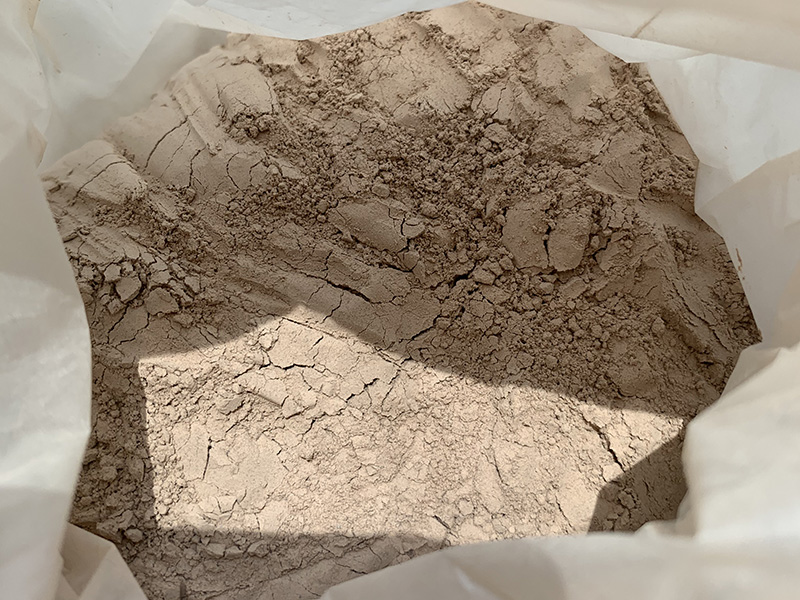

Workability is an important practical consideration for refractory mortar. Proper consistency allows for thin, uniform joints, typically between 1–2 mm, which improves heat resistance and structural strength. Refractory mortar is available in both dry powder form, mixed with water on site, and premixed wet form for immediate use. Good workability ensures efficient installation, reduces material waste, and improves construction quality.

Refractory mortar is widely used across multiple industries. In iron and steel production, it bonds refractory bricks in blast furnaces, ladles, and reheating furnaces. In cement and lime plants, refractory mortar is essential for kiln linings and preheaters exposed to abrasion and thermal cycling. In glass manufacturing, it ensures tight joints in furnace walls and regenerators, helping maintain temperature control and product quality. Refractory mortar is also commonly used in power plants, petrochemical facilities, and waste incineration systems.

Correct selection and application of refractory mortar are crucial for achieving optimal performance. The mortar type should always match the brick chemistry and operating conditions. After installation, controlled drying and gradual heating are required to remove moisture safely and allow the refractory mortar to develop full strength. Improper curing can lead to steam pressure, joint cracking, and reduced service life.

As industrial equipment continues to operate at higher temperatures and under more demanding conditions, refractory mortar remains a fundamental component of reliable refractory systems. Its ability to bond, seal, and protect refractory structures makes refractory mortar indispensable in ensuring safety, efficiency, and long-term performance in high-temperature applications.

Inquiry Now

Please leave your e-mail and we will contact you as soon as possible

contact us

Your satisfaction is our top priority. Whether you have questions, need support, or want to share feedback, our dedicated team is ready to assist you every step of the way.