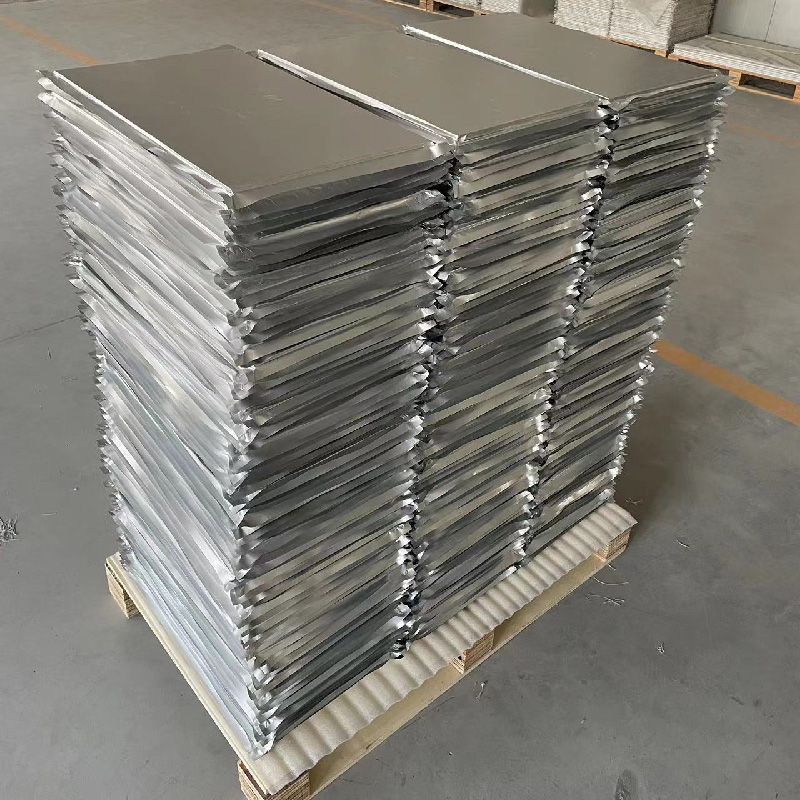

Nano Microporous Board – The Ultimate High-Temperature Insulation Solution for Industrial Applications

Introduction

In industries where extreme heat resistance and superior thermal insulation are critical, microporous insulation board stands out as a revolutionary solution. This high-tech insulation works great in extreme heat, saving energy and lasting longer. Whether you're in metallurgy, petrochemicals, power generation, or aerospace, our nano insulation panel ensures optimal thermal management while reducing energy costs.

Discover why leading industries trust our nano insulation boards for their most demanding applications.

Why Choose Nano Microporous Board?

1. Exceptional Thermal Insulation Performance

Ultra-Low Thermal Conductivity (as low as 0.020 W/m·K at 600°C)

High-Temperature Resistance (up to 1000°C+)

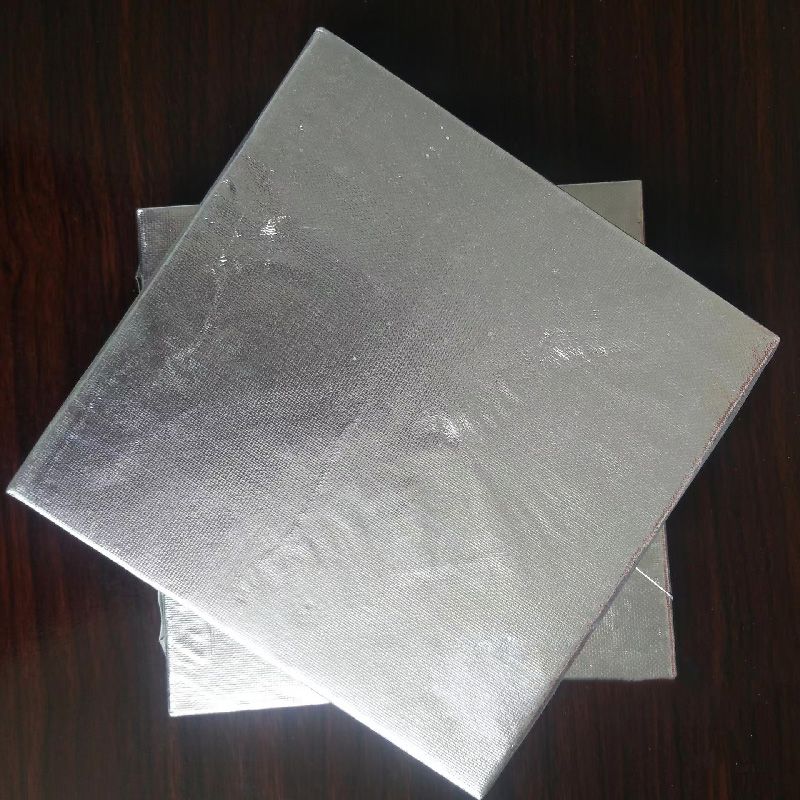

Microporous Structure minimizes heat transfer through conduction, convection, and radiation

2. Lightweight & Space-Saving

Low Density (200-300 kg/m³) reduces structural load

Thin & Compact design maximizes space efficiency

3. Superior Fire Resistance & Safety

Non-flammable (A1 fire rating)

Zero hazardous emissions under extreme heat

4. Durability & Long Service Life

Resists thermal shock & mechanical stress

Chemical properties - not affected by oils, acids or alkalis

5. Energy & Cost Efficiency

50% better heat blocking than standard insulation.

Lowers fuel consumption & CO₂ emissions

Technical Index

Item | Microporous hard board |

Density (kg/m3) | 280-300 |

Maximum operating temperature(℃) | 900 |

Compressive strength(Mpa) | ≥0.30 |

Linear Change 900℃x24h(%) | ≤ 2 |

Thermal Conductivity(w/m.k) | 0.022 (Mean 100℃) |

0.023 (Mean 200℃) | |

0.025 (Mean 300℃) | |

0.027 (Mean 400℃) | |

0.031 (Mean 500℃) | |

Covering Materials | Aluminum Foil/ PE Foil |

Key Applications & Industry Solutions

Steel & Metallurgy

Ladle & tundish linings: Nano Microporous Board reduces heat loss and maintains molten steel temperature.

Blast furnaces & reheating furnaces: Insulates walls, reduces energy consumption.

Heat treatment furnaces: Ensures uniform heating and consistent quality.

Petrochemical & Refining

Cracking furnaces & reformers: Maintains high temperatures, improves efficiency.

Boilers & pipelines insulation: Reduces heat loss, maintains fluid temperature.

High-temperature reactors: Protects reactor walls, ensures reaction progress.

Power Generation

Gas turbines & exhaust systems: Reduces heat loss, improves efficiency.

Boiler insulation: Maintains steam temperature, reduces fuel consumption.

Nuclear & thermal power plants: Ensures safety and efficiency.

Aerospace & Automotive

Jet engine insulation: Reduces heat transfer, improves engine reliability.

Exhaust heat shields: Protects components from intense heat.

Battery thermal management in EVs: Maintains stable battery temperature.

General Industrial Furnaces & Kilns

Ceramic & glass manufacturing: Ensures uniform firing and melting.

Cement & lime kilns: Reduces heat loss, improves efficiency.

Heat recovery systems: Maximizes waste heat recovery.

Easy Installation & Maintenance

Cutting & Shaping

Nano Microporous Board can be easily cut with standard tools and is available in customizable pre-cut panels.

Installation Methods

Mechanical Fixing: Uses high-temperature anchors and screws.

Adhesive Bonding: Uses refractory cement or high-temperature adhesives.

Layered Insulation Systems: Combines with other materials for maximum efficiency.

Maintenance Tips

Regular inspection and replacement of damaged sections without full system overhaul.

Our Service & Support

Custom Solutions – Tailored sizes, shapes, and densities

Technical Consultating – Expert advices on optimal insulation design

Fast Global Shipping – Reliable logistics for urgent orders

After-Sales Support – Installation guides & troubleshooting

What Our Customers Say

"Switching to high-temperature nano board reduced our furnace energy consumption by 30%. Highly recommended!"

"The lightweight design made installation effortless, and the heat retention is outstanding."

"Exceptional durability even in our 950°C kiln environment. Zero degradation after 3 years!"

Get Your Nano Microporous Board Today!

Upgrade your thermal insulation with the best thermal insulation nano board on the market. Contact us now for a free quote, sample, or technical consultation!

Inquiry Now

Please leave your e-mail and we will contact you as soon as possible

contact us

Your satisfaction is our top priority. Whether you have questions, need support, or want to share feedback, our dedicated team is ready to assist you every step of the way.