85% of Top Cement Plants Use This Refractory Material—Here’s Why

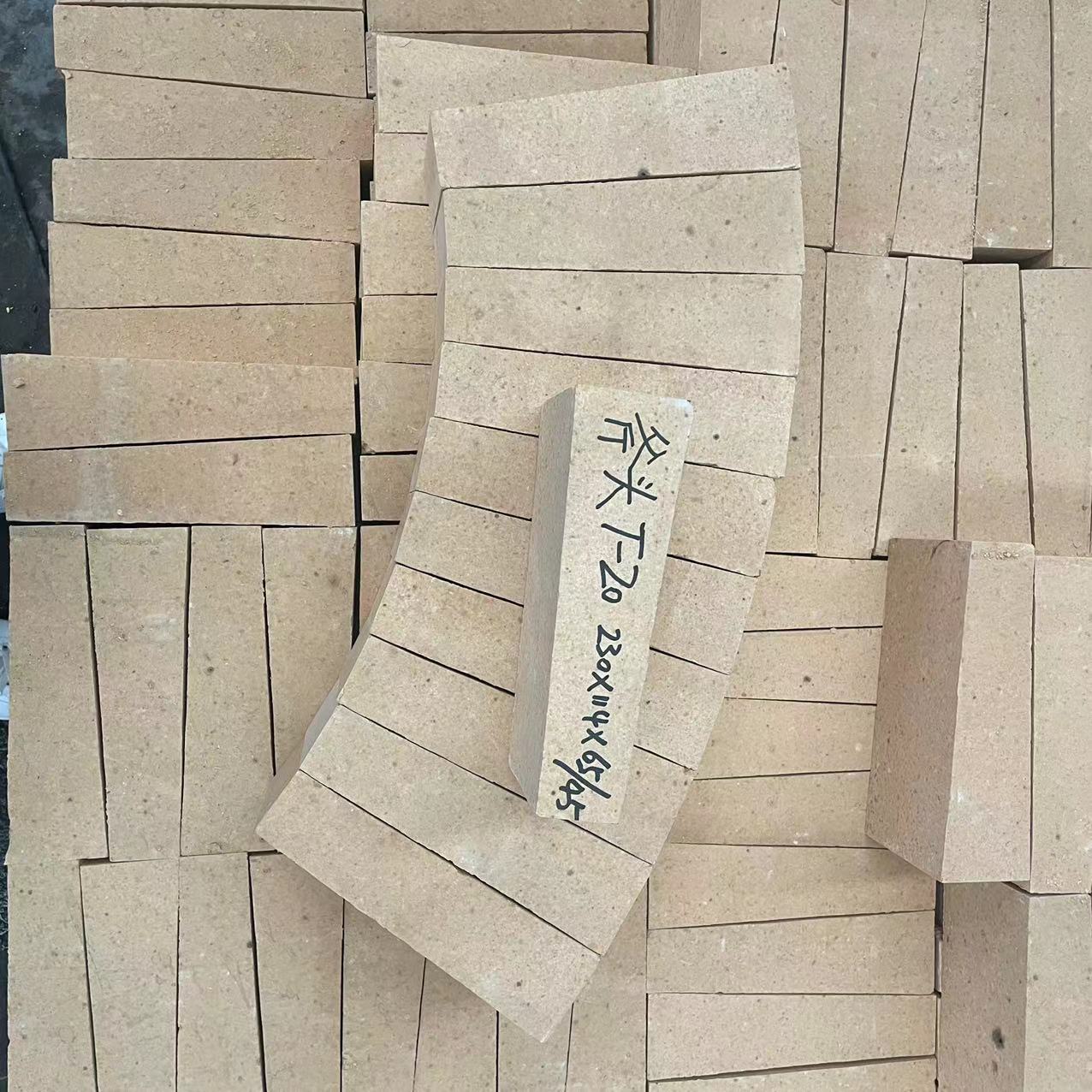

In the high-stakes world of cement production, where kilns operate at temperatures exceeding 1,450°C, the choice of refractory material can make or break operational efficiency. A striking industry statistic reveals that 85% of the world’s top cement plants rely on a specific refractory material to keep their kilns running smoothly: high-alumina refractory bricks. This preference isn’t arbitrary—these refractory bricks offer a unique blend of durability, cost-effectiveness, and performance that aligns perfectly with the demands of cement manufacturing. Let’s explore why high-alumina refractory bricks have become the gold standard.

The Unique Challenges of Cement Kilns for Refractory Materials

Cement kilns subject refractory materials to some of the harshest conditions in industrial settings. From the preheater to the burning zone, refractory materials must withstand extreme heat, rapid temperature fluctuations, and constant contact with abrasive raw materials like limestone and clay. The burning zone, in particular, reaches temperatures up to 1,600°C, where molten clinker (the precursor to cement) flows over the kiln lining, causing severe erosion and chemical corrosion.

Traditional refractory materials, such as fire clay bricks, often fail under these conditions, leading to frequent kiln shutdowns for repairs. A single unplanned shutdown can cost a cement plant tens of thousands of dollars in lost production, making the search for reliable refractory materials a top priority. This is where high-alumina refractory bricks step in, addressing these challenges head-on.

Why High-Alumina Refractory Bricks Dominate in Top Cement Plants

1. Superior Heat Resistance

High-alumina refractory bricks, defined by their alumina content (typically 40–90%), excel in high-temperature environments. Their ability to maintain structural integrity at temperatures exceeding 1,700°C makes them ideal for the burning zone of cement kilns, where other refractory materials would soften or deform. This heat resistance directly translates to longer kiln runs—top cement plants report 30–40% fewer shutdowns after switching to high-alumina refractory bricks.

2. Resistance to Chemical Corrosion

Cement production involves complex chemical reactions, and the clinker formed in kilns is highly alkaline. This alkalinity can break down weaker refractory materials over time, leading to lining degradation. High-alumina refractory bricks, however, are chemically stable in alkaline environments, forming a protective layer that resists corrosion. This property is critical for extending the lifespan of kiln linings, with top plants achieving 6–12 months of continuous operation before needing refractory replacements.

3. Abrasion Resistance

The raw materials and clinker in cement kilns are highly abrasive, constantly scraping against the kiln lining. High-alumina refractory bricks have a dense, hard microstructure that withstands this abrasion, reducing wear and tear. Compared to fire clay bricks, they last 2–3 times longer in abrasive zones like the kiln inlet and preheater, further lowering maintenance costs.

4. Cost-Effectiveness

While high-alumina refractory bricks have a higher upfront cost than some alternatives, their longevity and performance make them more cost-effective in the long run. Top cement plants calculate that the reduced downtime, lower replacement frequency, and improved kiln efficiency result in a 25–30% lower total cost of ownership compared to using cheaper refractory materials. This ROI is a key reason 85% of leading plants prioritize high-alumina refractory bricks.

A global cement manufacturer with 20+ plants recently shared its experience: after switching all kilns to high-alumina refractory bricks, annual maintenance costs dropped by $1.2 million, and kiln availability increased from 85% to 92%. “The reliability of high-alumina refractory bricks transformed our operations,” said the plant manager. “We’re producing more cement with fewer interruptions, and our bottom line reflects that.”

In conclusion, the dominance of high-alumina refractory bricks in top cement plants is no accident. Their heat resistance, chemical stability, abrasion resistance, and cost-effectiveness address the unique challenges of cement kilns, delivering tangible benefits for operational efficiency and profitability. For cement plants aiming to join the industry’s elite, investing in high-alumina refractory bricks isn’t just a choice—it’s a strategic imperative.

Inquiry Now

Please leave your e-mail and we will contact you as soon as possible

contact us

Your satisfaction is our top priority. Whether you have questions, need support, or want to share feedback, our dedicated team is ready to assist you every step of the way.