<script type="application/ld+json">

{

"@context": "https://schema.org",

"@type": "NewsArticle",

"@id": "https://www.laurelrefractory.com/high-purity-magnesia-brick-for-extreme-thermal-conditions.html#news",

"headline": "High Purity Magnesia Brick: A Reliable Refractory Material for Extreme Thermal Conditions",

"alternativeHeadline": "High Purity Magnesia Brick Provides Superior Refractoriness, Chemical Resistance, and Mechanical Strength for High-Temperature Furnaces",

"description": "High purity magnesia brick is an ideal refractory material for extreme thermal conditions, offering outstanding refractoriness, chemical stability, mechanical reliability, and thermal stability in steelmaking, cement, lime, and glass furnaces.",

"url": "https://www.laurelrefractory.com/high-purity-magnesia-brick-for-extreme-thermal-conditions.html",

"datePublished": "2026-01-08",

"dateModified": "2026-01-08",

"image": [

"https://vhost-ln-s04-cdn.hcwebsite.com/ede252c5b657426654db5cbc45ee5c62/res/en/20251111/c7489ae15ea1668c.jpg?v=C8Ksg47k"

],

"author": {

"@type": "Organization",

"name": "Laurel Refractory",

"url": "https://www.laurelrefractory.com/"

},

"publisher": {

"@type": "Organization",

"name": "Laurel Refractory",

"url": "https://www.laurelrefractory.com/"

},

"articleSection": "Refractory Materials / Magnesia Bricks",

"keywords": [

"high purity magnesia brick",

"MgO brick",

"refractory material",

"high-temperature furnace brick",

"steelmaking refractory",

"cement kiln brick",

"lime kiln brick",

"glass furnace brick",

"chemical resistance",

"mechanical strength"

],

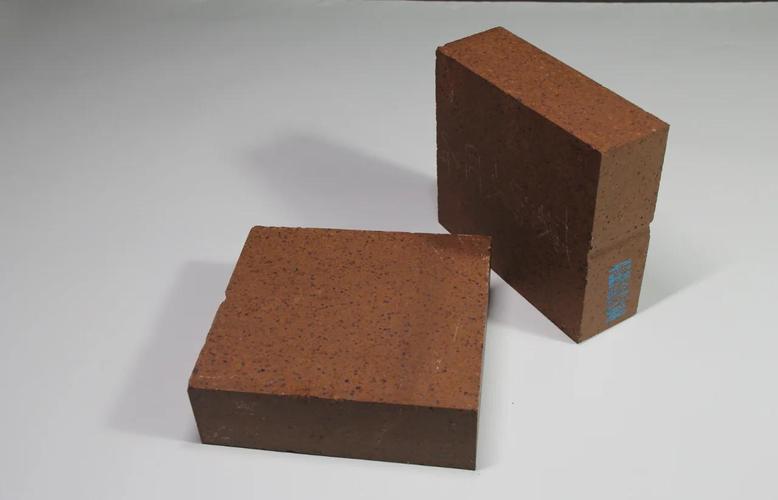

"articleBody": "High purity magnesia brick, with MgO content exceeding 97%, is engineered for extreme thermal environments. Its dense and uniform crystal structure ensures exceptional refractoriness, withstanding continuous exposure at temperatures above 2800°C. The material demonstrates excellent chemical stability, resisting basic slags and alkaline attack, which prolongs furnace lining life. Mechanically, it maintains strength under heavy loads, vibration, and abrasion, reducing deformation and cracking during long production cycles. Thermal stability under fluctuating temperatures further ensures structural integrity and minimizes spalling. Widely applied in steelmaking furnaces (electric arc furnaces, ladles, secondary refining), cement rotary kilns, lime kilns, and glass melting furnaces, high purity magnesia brick supports optimized refractory lining structures, reduces heat loss, and enhances operational efficiency. Its long service life and reliability make it a strategic choice for safe, efficient, and sustainable high-temperature industrial operations."

}

</script>