High-Performance Ceramic Fiber Board: Upgraded Thermal Protection for Modern Industrial Systems

In high-temperature industrial environments, insulation materials must deliver far more than simple thermal resistance—they must combine stability, durability, energy efficiency, and safety. Among the numerous refractory and insulation solutions available today, Ceramic fiber board has become one of the most advanced and versatile materials widely adopted across metallurgical, chemical, power generation, and heat-processing industries. With the growing global focus on energy conservation and industrial modernization, Ceramic fiber board is entering a new stage of rapid development and technological advancement.

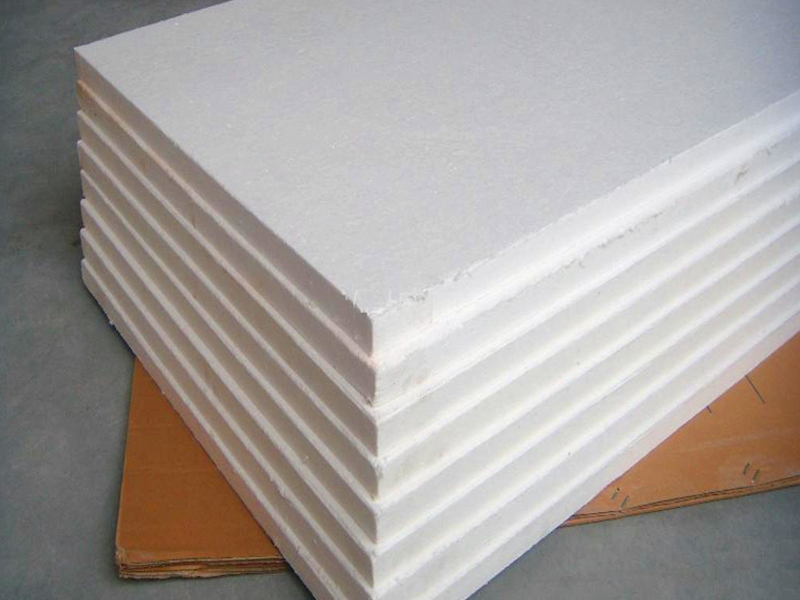

Manufactured through a precision vacuum-forming process, Ceramic fiber board is engineered from high-purity aluminum-silicate fiber and selected inorganic binders. This controlled production method ensures uniform density throughout the board while maintaining excellent dimensional stability. Unlike traditional refractory boards that tend to crack or deform under rapid temperature changes, Ceramic fiber board offers outstanding thermal shock resistance, allowing it to maintain structural integrity even under extreme swings from heating to cooling cycles.

One of the most significant advantages of Ceramic fiber board is its exceptionally low thermal conductivity, which greatly reduces heat loss in industrial applications. This characteristic directly contributes to lower fuel consumption, improved system efficiency, and enhanced temperature control inside furnaces, kilns, reformers, and heat-treatment equipment. For industries where every degree of precision influences final product quality—such as glass manufacturing, ceramic sintering, or alloy heat treatment—Ceramic fiber board provides the stability required for high-accuracy thermal processes.

Beyond thermal performance, Ceramic fiber board is widely recognized for its lightweight structure and ease of installation. The material can be cut, drilled, or machined into various shapes without compromising strength, enabling engineers to design customized insulation structures that are difficult to achieve using dense fire bricks or calcium silicate materials. This adaptability makes Ceramic fiber board ideal for furnace linings, fireproof partitions, expansion joints, burner blocks, and equipment insulation panels. Its ease of handling significantly reduces construction time and labor costs, especially in large-scale retrofit or shutdown maintenance projects.

Durability is another defining feature of modern Ceramic fiber board technologies. New formulations enhance compressive strength, abrasion resistance, and chemical stability, allowing the board to withstand corrosive gases, molten slag contact, and long-term exposure to high-velocity hot air streams. These improvements extend the service life of linings and reduce unplanned downtime—an essential factor for continuous-operation industries such as petrochemical and steel production.

Environmental and regulatory factors are also accelerating the adoption of Ceramic fiber board. As companies worldwide implement low-carbon strategies and seek insulation materials with higher efficiency and lower emissions, Ceramic fiber board has emerged as a preferred choice due to its longevity, recyclable components, and stable performance across extended operating cycles. Its non-combustible properties and resistance to flame spread further align with modern fire-safety standards, providing additional protection for industrial systems and personnel.

From a market perspective, global demand for Ceramic fiber board continues to rise. Manufacturers are investing in advanced fiber spinning technologies, automated molding lines, and high-purity raw material formulations to meet growing international standards. New product variants—including high-temperature series, erosion-resistant series, and structural-reinforced series—are expanding the application range of Ceramic fiber board, enabling improved insulation performance in more complex and demanding environments.

As industries pursue higher thermal efficiency, extended equipment lifespan, and sustainable production methods, Ceramic fiber board will remain a critical material driving innovation in the insulation and refractory sector. Its combination of lightweight design, excellent heat resistance, operational reliability, and long-term cost savings positions Ceramic fiber board as a forward-looking solution capable of supporting the evolving needs of modern industrial systems.

Inquiry Now

Please leave your e-mail and we will contact you as soon as possible

contact us

Your satisfaction is our top priority. Whether you have questions, need support, or want to share feedback, our dedicated team is ready to assist you every step of the way.