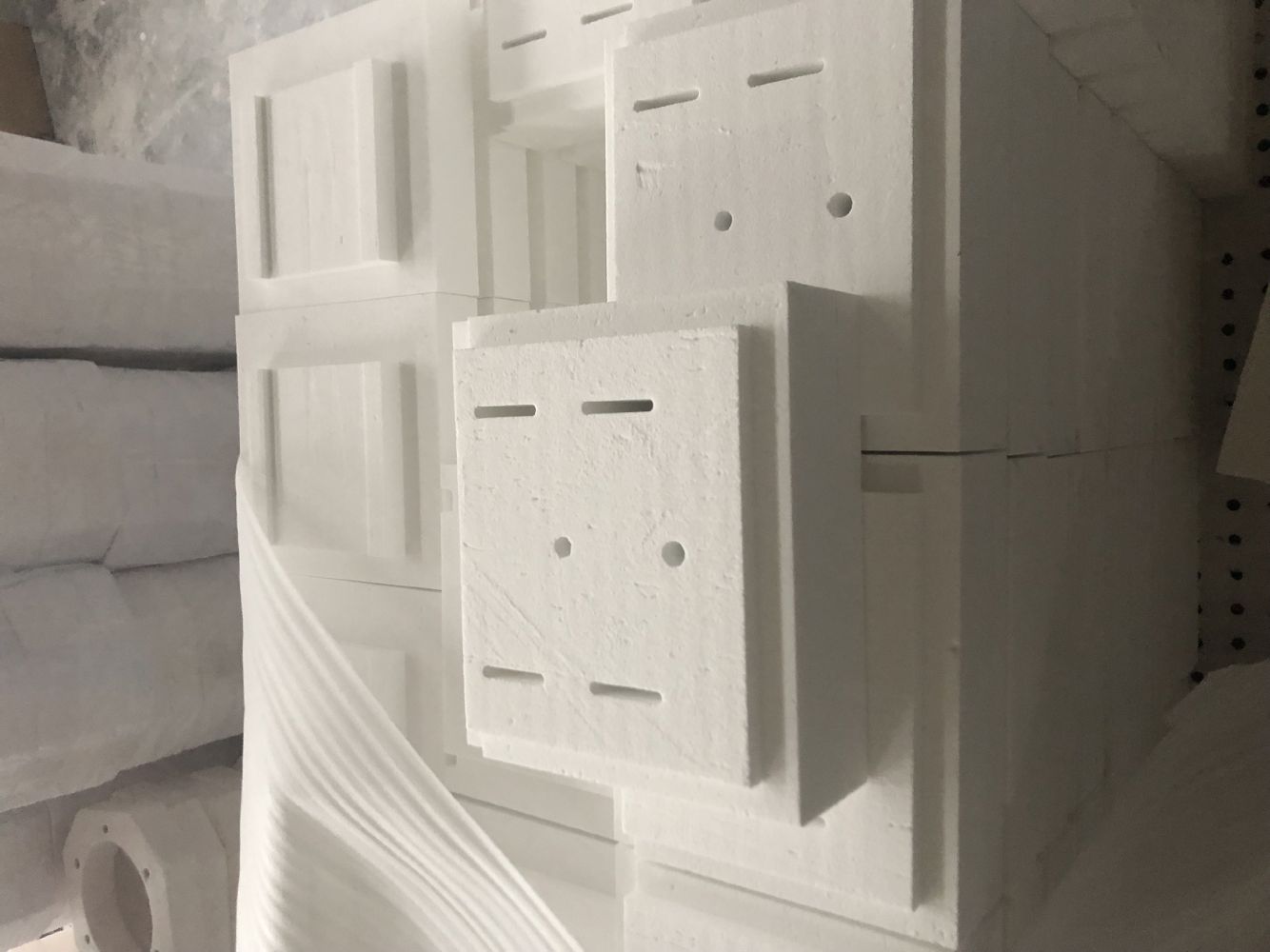

Unveiling the Exceptional Properties of Polycrystalline Fiberboard

Polycrystalline fiberboard has emerged as a revolutionary material in various high - performance applications, thanks to its distinct set of properties. This article explores the key characteristics that make polycrystalline fiberboard stand out.

High - Temperature Resistance

At the forefront of polycrystalline fiberboard's properties is its outstanding high - temperature resistance. Composed mainly of polycrystalline oxides, such as alumina, it can endure continuous exposure to temperatures well above 1500°C. In industrial settings like high - temperature furnaces in the metal - smelting industry, this property is invaluable. For instance, in a large - scale steel - making plant, the arc furnaces reach temperatures of around 1600°C during the melting process. Polycrystalline fiberboard lining these furnaces not only safeguards the furnace shell from the searing heat but also plays a crucial role in maintaining the high - temperature environment. This enables more efficient melting of scrap metal and raw materials, reducing the overall smelting time and energy consumption.

In the ceramic industry, kilns used for firing high - end porcelain and refractory ceramics operate at extremely high temperatures. Polycrystalline fiberboard is widely employed in these kilns. It ensures that the internal temperature remains stable throughout the firing cycle, which is essential for achieving the desired quality and finish of the ceramic products. Without this high - temperature - resistant material, the kilns would be more prone to damage, and the firing process could be less consistent, leading to a higher number of defective products.

Low Thermal Conductivity

Another remarkable property of polycrystalline fiberboard is its low thermal conductivity. Heat transfer through the material is significantly inhibited, making it an excellent thermal insulator. In applications where energy conservation is crucial, such as in industrial ovens and boilers, polycrystalline fiberboard reduces heat loss to the surroundings. In a food - processing factory, large industrial ovens used for baking bread and pastries require precise temperature control and energy efficiency. By using polycrystalline fiberboard as insulation, these ovens can maintain a consistent baking temperature while consuming less energy. This not only cuts down on utility bills but also extends the lifespan of the oven components, as they are subjected to less thermal stress.

In the power generation sector, boilers used in coal - fired power plants operate at high temperatures. Polycrystalline fiberboard is installed in the boiler insulation systems. It effectively minimizes heat loss, allowing the boilers to operate more efficiently. As a result, more energy from the burning coal can be converted into steam, which in turn drives the turbines to generate electricity. This improved energy efficiency not only benefits the power plant economically but also contributes to reducing the overall carbon footprint by consuming less fuel.

Excellent Mechanical Strength

Despite its lightweight composition, polycrystalline fiberboard exhibits impressive mechanical strength. It can withstand mechanical stress, vibrations, and thermal shock without significant damage. In aerospace applications, where components need to endure harsh conditions during flight, polycrystalline fiberboard is used in areas like engine compartments. For example, in a jet engine, the components near the combustion chamber are exposed to intense heat, high - velocity gas flow, and mechanical vibrations. Polycrystalline fiberboard is used to insulate and protect these components. It can handle the mechanical stress from the engine's vibrations while also shielding against the high - temperature environment, ensuring the safe and efficient operation of the aircraft.

In the automotive racing industry, high - performance engines generate a great deal of heat and mechanical stress. Polycrystalline fiberboard is sometimes used in the engine bay insulation. It helps in reducing heat transfer to the surrounding components, protecting them from thermal damage. Additionally, it can withstand the vibrations and shocks associated with high - speed driving and rapid acceleration, maintaining its integrity and providing long - term protection to the engine and related systems.

In conclusion, the combination of high - temperature resistance, low thermal conductivity, and excellent mechanical strength makes polycrystalline fiberboard a material of choice for a wide range of industries, from manufacturing to aerospace. As technology continues to advance, the applications of polycrystalline fiberboard are likely to expand further, driven by its unique and highly desirable properties.

Inquiry Now

Please leave your e-mail and we will contact you as soon as possible

contact us

Your satisfaction is our top priority. Whether you have questions, need support, or want to share feedback, our dedicated team is ready to assist you every step of the way.