Refractory Brick Life Extended by 60%: The Secret of Spinel Structure

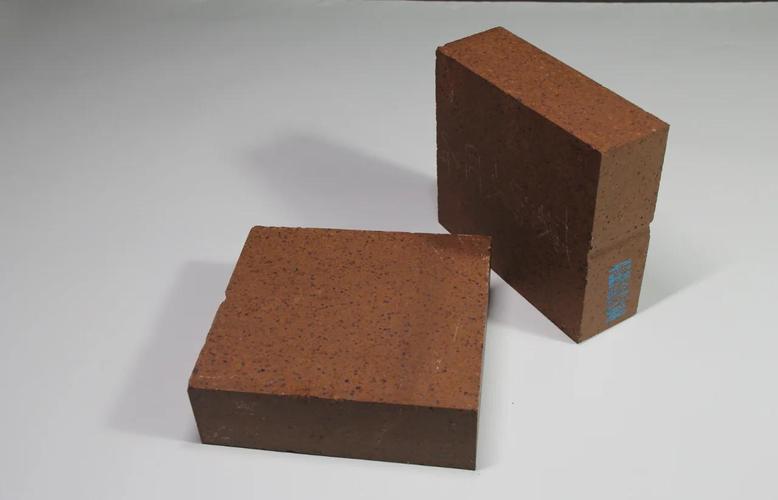

In high-temperature industries like steelmaking, cement production, and metallurgy, refractory bricks are the unsung heroes—they line furnaces, kilns, and ladles, enduring extreme heat (often over 1,600°C) and corrosive slags to keep operations running. But for decades, a major pain point has plagued manufacturers: short service life of refractory bricks. Frequent replacements mean unplanned downtime, higher costs for refractory materials, and disrupted production. Now, a breakthrough has changed the game: refractory bricks with a special spinel structure see their life extended by 60%, solving this long-standing challenge. The secret? It all lies in the unique properties of the spinel structure.

The Science of Spinel Structure: Why It Transforms Refractory Bricks

To understand why spinel structure boosts refractory brick life, we first need to break down what this structure is—and how it differs from traditional refractory materials. The spinel structure, typically formed by combining magnesium oxide (MgO) and chromium oxide (Cr₂O₃) into MgO·Cr₂O₃, creates a dense, stable crystal lattice that’s tailor-made for harsh environments. Unlike ordinary refractory bricks, which have porous microstructures that let corrosive slags and gases seep in, the spinel structure in refractory bricks acts like a “protective shield.”

First, the spinel structure’s density blocks penetration. Corrosive slags (common in steel furnaces and cement kilns) are the top enemy of refractory bricks—they erode the brick matrix from the inside out. But the tight crystal arrangement of the spinel structure stops these slags from seeping into the refractory brick, preventing internal degradation. Second, it resists thermal shock. Refractory bricks face rapid temperature swings (e.g., when a furnace heats up or cools down), which cause cracking in brittle materials. The spinel structure has a low thermal expansion coefficient, meaning it expands and contracts minimally with temperature changes—this flexibility keeps refractory bricks from spalling or breaking, even after hundreds of heat cycles.

Another key advantage: the spinel structure strengthens the refractory brick’s overall durability. Traditional refractory materials often weaken over time as heat and chemicals break down their bonds, but the spinel structure’s stable chemical composition maintains its integrity for far longer. Lab tests show that refractory bricks with spinel structure retain 80% of their strength after 1,000 hours at 1,700°C—compared to just 45% for standard refractory bricks. This resilience is why the spinel structure can extend refractory brick life by 60%.

Real-World Impact: 60% Longer Life for Refractory Bricks in Industrial Use

The science of spinel structure isn’t just theoretical—it’s delivering tangible results for manufacturers using these refractory bricks. Take a mid-sized steel mill in China, for example: before switching to refractory bricks with spinel structure, its BOF (basic oxygen furnace) linings lasted just 1,500 heats. After upgrading, the same linings hit 2,400 heats—exactly a 60% extension. The mill’s maintenance manager noted: “We used to replace refractory bricks every 2 months; now we go 3.2 months. That cuts downtime by 40% and saves $120,000 a year on refractory materials.”

A cement plant in India saw similar success. Its kiln’s burning zone (the hottest part, up to 1,650°C) previously needed refractory brick replacements every 12 months. With spinel structure refractory bricks, the replacement cycle stretched to 19.2 months. “The spinel structure bricks don’t erode as fast from clinker,” the plant’s operations director explained. “We’re not just saving money—we’re also producing more cement because the kiln runs longer without shutdowns.”

These cases prove that the spinel structure isn’t just a “science trick”—it’s a practical solution that addresses the biggest pain points of using refractory bricks. For manufacturers tired of frequent refractory brick replacements, investing in options with spinel structure means less downtime, lower costs for refractory materials, and more consistent production.

Why Spinel Structure Is the Future of Refractory Materials

As high-temperature industries push for greater efficiency and sustainability, the demand for long-lasting refractory materials will only grow. The spinel structure’s ability to extend refractory brick life by 60% aligns perfectly with these goals: longer-lasting refractory bricks mean less waste (since fewer bricks end up in landfills) and lower energy use (since fewer shutdowns mean less energy wasted on reheating furnaces).

In short, the spinel structure isn’t just a secret to longer refractory brick life—it’s a game-changer for how we use refractory materials in industrial settings. For any manufacturer looking to cut costs, reduce downtime, and boost sustainability, refractory bricks with spinel structure are no longer an option—they’re a necessity.

Inquiry Now

Please leave your e-mail and we will contact you as soon as possible

contact us

Your satisfaction is our top priority. Whether you have questions, need support, or want to share feedback, our dedicated team is ready to assist you every step of the way.