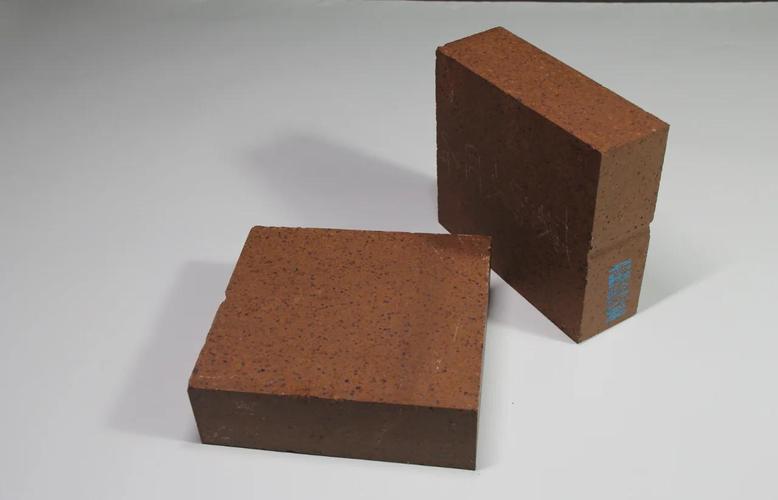

Magnesia Refractory Bricks: The Backbone of High-Temperature Industrial Performance

In the demanding world of high-temperature furnaces, converters, and kilns, magnesia refractory bricks play a vital role in ensuring the stability and durability of thermal equipment. Known for their superior resistance to basic slags and exceptional performance under extreme conditions, magnesia bricks are an indispensable material in steelmaking, non-ferrous metallurgy, cement, and glass industries.

Material Composition and Properties

Magnesia refractory bricks are primarily composed of magnesium oxide (MgO), typically with a purity above 90%. This high MgO content gives the bricks outstanding alkali resistance, high refractoriness, and strong mechanical strength at elevated temperatures. Depending on the production process and raw materials used, magnesia bricks can be classified into several types:

Sintered Magnesia Bricks: Made from natural magnesite sintered at high temperatures (1500–1750°C), offering strong structure and good corrosion resistance.

Fused Magnesia Bricks: Produced from fused magnesia through electro-fusion, these bricks exhibit superior density, low porosity, and enhanced durability against molten slags.

Magnesia-Carbon Bricks: A combination of magnesia grains and graphite, providing excellent thermal shock resistance and slag penetration resistance, widely used in steel converters and ladles.

Magnesia-Chrome Bricks: Blended with chromium oxide for improved resistance to acidic slags and spalling, commonly used in cement rotary kilns and non-ferrous furnaces.

Performance Advantages

The exceptional performance of magnesia refractory bricks lies in their ability to withstand the harshest environments without losing structural integrity:

High Refractoriness: Withstanding temperatures exceeding 1800°C, magnesia bricks maintain mechanical strength and volume stability under continuous exposure to heat.

Strong Basic Slag Resistance: Unlike silica or alumina refractories, magnesia bricks resist attack from basic slags rich in CaO and FeO, making them ideal for steel refining and metallurgical furnaces.

Excellent Thermal Conductivity: Efficiently transfers heat, promoting uniform temperature distribution within furnaces and reducing thermal stress buildup.

Superior Load-Bearing Capacity: Maintains compressive strength even under heavy mechanical loads in rotary kilns and steelmaking vessels.

Thermal Shock and Erosion Resistance: Advanced magnesia-carbon formulations enhance resilience to thermal cycling and corrosive slags, ensuring long service life.

Industrial Applications

Magnesia refractory bricks are widely applied across industries where extreme temperature and chemical stability are crucial:

Iron & Steel Industry: Used in basic oxygen furnaces (BOF), electric arc furnaces (EAF), ladles, and tundishes. Magnesia-carbon bricks are particularly effective in slag zones and impact areas.

Cement Industry: Magnesia-chrome and direct-bonded magnesia bricks are employed in rotary kiln linings, transition zones, and clinker coolers, providing excellent thermal shock resistance.

Non-Ferrous Metallurgy: Protects furnaces and converters in copper, nickel, and zinc smelting operations from corrosion by aggressive slags.

Glass Industry: Utilized in regenerators and furnaces due to their strong resistance to alkaline vapors and molten glass corrosion.

Lime and Dolomite Kilns: Offers excellent durability under high heat and basic dust conditions.

Manufacturing and Quality Control

Our magnesia refractory bricks are produced with high-purity fused magnesia and advanced sintering technology. Each batch undergoes rigorous chemical composition analysis, bulk density measurement, and thermal shock testing to ensure consistent performance and long service life. Strict process control ensures minimal porosity, precise dimensions, and high structural uniformity.

Advantages in Modern Industry

By incorporating magnesia refractory bricks, industries benefit from:

Reduced maintenance frequency and operational downtime

Improved furnace efficiency and lower energy consumption

Stable furnace performance with minimal deformation or spalling

Extended refractory lining lifespan and reduced overall cost

In modern metallurgy and thermal processing, magnesia refractory bricks stand as a cornerstone material—delivering the perfect balance of strength, stability, and corrosion resistance. Their ability to endure extreme temperatures and chemically aggressive environments makes them indispensable in any high-performance refractory system. Whether used in steel refining, cement production, or non-ferrous metallurgy, these bricks provide the durability and reliability needed to keep furnaces running efficiently and safely.

Inquiry Now

Please leave your e-mail and we will contact you as soon as possible

contact us

Your satisfaction is our top priority. Whether you have questions, need support, or want to share feedback, our dedicated team is ready to assist you every step of the way.