Why Ceramic Fiber Paper is a Must-Have in Industrial and Beyond

Ceramic fiber paper, a remarkable material in the realm of high-temperature insulation, has been making significant strides in various industries.

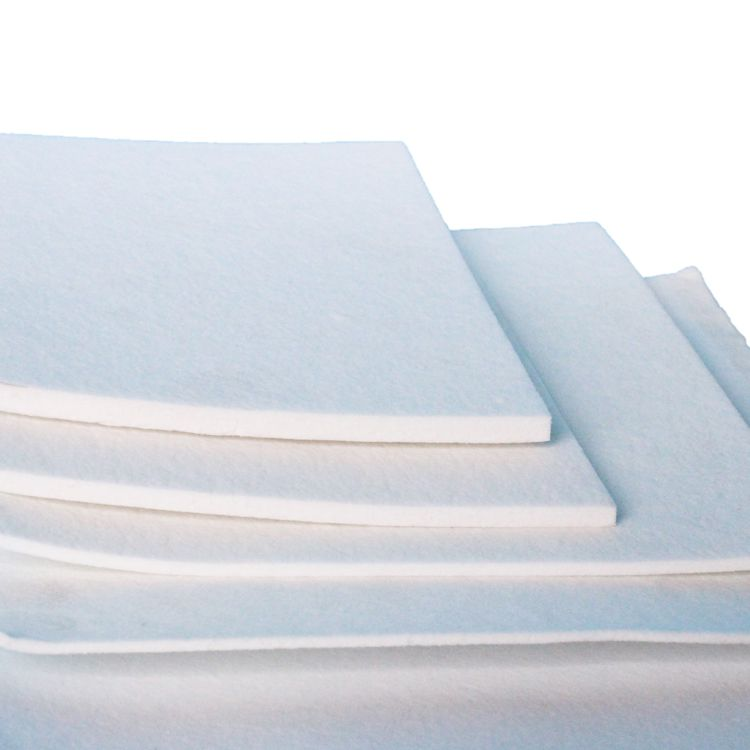

Product Introduction

Thermal ceramic fiber paper is craf ted from high-quality ceramic fibers. These fibers are typically made from alumina and silica, which are blended and processed through advanced manufacturing techniques. The resulting paper has a unique fibrous structure that gives it outstanding properties. Roll ceramic fiber paper is light weight yet highly durable, capable of withstanding extreme temperatures without significant degradation.

Technical Index

Item | STD PAPER | HA PAPER | HZ PAPER | |

Classification Temperature(℃) | 1260 | 1350 | 1450 | |

Working Temperature(℃) | 1100 | 1200 | 1350 | |

Color | White | White | Pure White | |

Density(kg/m3) | 180-220 | 180-220 | 180-220 | |

Thermal Conductivity(W/m·k) | 0.08(400℃) 0.12(600℃) 0.20(800℃) | 0.08(400℃) 0.13(600℃) 0.19(800℃) | 0.08(400℃) 0.13(600℃) 0.18(800℃) | |

Tensile Strength(Mpa) | 0.40 | 0.70 | 0.70 | |

Chemical Composition | Al2O3(%) | 42-45 | 45-50 | 35-38 |

SiO2(%) | 54-57 | 49-54 | 44-49 | |

ZrO2(%) | - | - | 15-17 | |

Function

One of the primary functions of refractory ceramic fiber paper is its excellent thermal insulation. Ceramic fiber insulation paper acts as a barrier, effectively reducing heat transfer and thus maintaining lower temperatures in areas where it is applied. This helps in conserving energy and protecting adjacent components or structures from the adverse effects of high heat. Insulation paper also has good sound absorption capabilities, making it useful in applications where noise reduction is desired along with thermal insulation. Moreover, ceramic fiber wool paper is chemically inert in many environments, which means it resists corrosion and chemical reactions, ensuring its long-term stability and reliability.

Applications

In the field of industrial furnaces, ceramic fiber sealing paper is widely used. Heat resistant paper lines the interiors of furnaces, kilns, and ovens, providing insulation that allows for more efficient heating processes and reduced heat loss. This not only saves energy but also extends the life of your furnace equipment. In the automotive industry, fiber blanket hotmelt kiln paper can be found in exhaust systems and engine compartments. By insulating the hot parts, it helps in improving overall vehicle performance and reducing the heat impact on surrounding components. Additionally, in the aerospace field, resistant paper is used in thermal protection systems. Insulaton paper helps in safeguarding spacecraft and aircraft components from the intense heat generated during high-speed flight or re-entry into the atmosphere. Ceramic fiber fireproof paper is also utilized in the manufacturing of heat shields for various industrial and consumer products, such as fireproof safes and heat-resistant gloves, where its ability to resist high temperatures and provide insulation is crucial for safety and functionality.

In conclusion, cotton fiber seal paper is an indispensable material with a wide range of applications. Its unique combination of properties makes it a top choice for industries dealing with high temperatures and insulation requirements. Whether it's in the heart of an industrial furnace or on a spacecraft hurtling through the cosmos, refractory paper continues to prove its worth and contribute to technological advancements and operational efficiencies.

Inquiry Now

Please leave your e-mail and we will contact you as soon as possible

contact us

Your satisfaction is our top priority. Whether you have questions, need support, or want to share feedback, our dedicated team is ready to assist you every step of the way.