Ceramic Fiber Wool: A Flexible Insulation Material for High-Temperature Industrial Applications

In modern high-temperature industries, thermal insulation materials must meet increasingly strict requirements for efficiency, durability, and adaptability. Ceramic fiber wool has become one of the most widely used insulation materials in furnace and thermal system design due to its lightweight structure, excellent heat resistance, and versatile application performance. As industries continue to pursue energy savings and stable operation, ceramic fiber wool remains a core component in advanced insulation solutions.

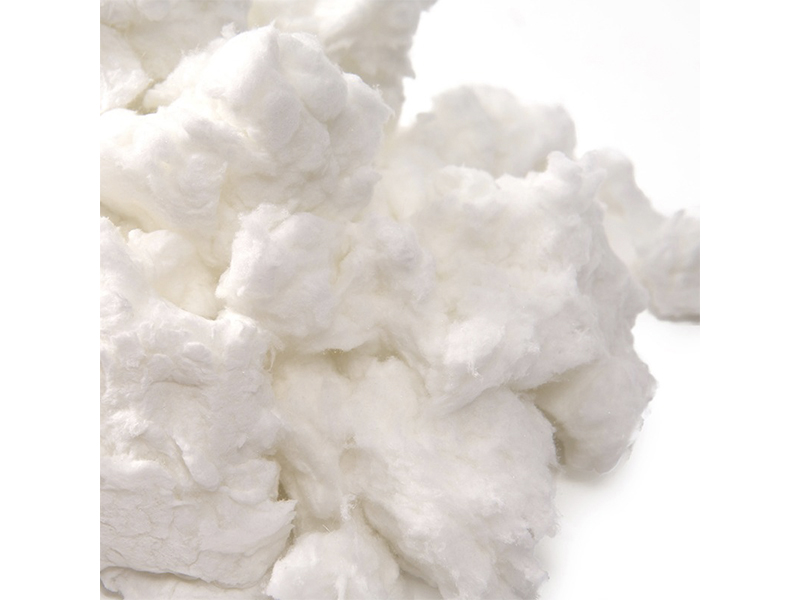

Ceramic fiber wool is produced by melting high-purity alumina and silica at extremely high temperatures, followed by fiberizing the molten material into fine, interwoven fibers. This process creates a soft, cotton-like structure with low density and high porosity. The resulting ceramic fiber wool traps air effectively, which significantly reduces heat transfer and provides excellent thermal insulation even under continuous high-temperature exposure.

One of the most important characteristics of ceramic fiber wool is its outstanding temperature resistance. Depending on grade, ceramic fiber wool can operate continuously at temperatures ranging from 1000°C to over 1400°C. This makes it suitable for direct contact with hot surfaces in industrial furnaces, kilns, and reactors. Unlike traditional dense refractories, ceramic fiber wool does not rely on mass to resist heat, but instead limits heat flow through its fibrous structure.

The low thermal conductivity of ceramic fiber wool contributes directly to improved energy efficiency. By reducing heat loss through furnace walls and equipment surfaces, ceramic fiber wool helps lower fuel consumption and stabilize internal temperatures. This advantage is especially valuable in energy-intensive industries such as steelmaking, petrochemical processing, and power generation.

Ceramic fiber wool also offers excellent thermal shock resistance. Industrial equipment often experiences rapid heating and cooling cycles during startup, shutdown, or process changes. The flexible fiber structure of ceramic fiber wool allows it to absorb thermal stress without cracking or spalling. This property makes ceramic fiber wool particularly suitable for intermittent furnaces and systems with frequent temperature fluctuations.

In practical applications, ceramic fiber wool is commonly used as bulk insulation, expansion joint packing, and backup lining material. It can be installed behind dense refractory linings to reduce heat loss or used to fill irregular gaps and complex geometries where rigid materials are difficult to apply. Ceramic fiber wool is also a key raw material for manufacturing ceramic fiber blankets, boards, papers, and modules.

From an installation perspective, ceramic fiber wool provides significant flexibility. It can be easily shaped, layered, or compressed to meet specific design requirements. This adaptability reduces installation time and labor costs while allowing precise thermal insulation in challenging areas. Ceramic fiber wool is often combined with anchoring systems or encapsulated in metal casings to enhance stability in high-velocity gas environments.

Chemical stability further enhances the reliability of ceramic fiber wool. The material resists attack from most acids, alkalis, and industrial gases, maintaining insulation performance in chemically aggressive atmospheres. This resistance supports long service life in applications such as chemical reactors, incinerators, and exhaust systems.

With increasing attention to health, safety, and environmental standards, low bio-soluble ceramic fiber wool has gained wider acceptance. These advanced formulations are designed to meet regulatory requirements while maintaining the thermal and mechanical properties expected from ceramic fiber wool. As regulations evolve, demand for environmentally responsible ceramic fiber wool continues to grow across global markets.

In long-term operation, ceramic fiber wool contributes to reduced maintenance frequency and extended equipment life. Lower shell temperatures reduce thermal stress on steel structures, while stable insulation performance helps maintain consistent operating conditions. These benefits translate into improved reliability and lower total operating costs.

Overall, ceramic fiber wool remains a vital insulation material in high-temperature industrial systems. Its combination of lightweight structure, excellent thermal insulation, thermal shock resistance, and installation flexibility makes it well suited for a wide range of applications. As industrial processes continue to demand higher efficiency and operational stability, ceramic fiber wool will continue to play an essential role in modern thermal insulation and refractory system design worldwide.

Inquiry Now

Please leave your e-mail and we will contact you as soon as possible

contact us

Your satisfaction is our top priority. Whether you have questions, need support, or want to share feedback, our dedicated team is ready to assist you every step of the way.