Calcium Silicate Board: A Modern Insulation Material Shaping the Future of Industrial and Architectural Protection

Across industries where thermal stability, fire resistance, and long-term durability are essential requirements, calcium silicate board has steadily become one of the most trusted insulation and structural materials. Manufactured from a blend of high-grade silica, calcium oxide, and reinforcing fibers, the calcium silicate board demonstrates remarkable performance under demanding temperatures while maintaining a lightweight and stable structure.

Engineered for High-Temperature Performance

The formulation of calcium silicate board follows a precise hydrothermal process that creates a strong, fine-grained insulation material capable of operating continuously in temperatures between 650°C and 1100°C. Its stable crystalline structure ensures minimal shrinkage and consistent thermal resistance during long-term exposure to heat.

Unlike ordinary gypsum sheets, the calcium silicate board is designed specifically to withstand extreme thermal loads. It maintains rigidity and flatness even after repeated heating cycles, making it suitable for industrial furnaces, kilns, and mechanical equipment insulation.

Mechanical Strength Paired With Low Thermal Conductivity

One notable advantage of calcium silicate board is its ability to combine mechanical durability with exceptional insulation efficiency. The rigid matrix resists compression and impact, allowing the material to support structural loads without crumbling. At the same time, its low thermal conductivity helps minimize heat loss, which reduces energy consumption in production facilities and improves equipment efficiency.

This balance of strength and insulation is one reason why the calcium silicate board is widely used in environments that require stable thermal barriers without compromising mechanical integrity.

A Reliable Choice for Industrial Applications

The adaptability of calcium silicate board has led to its growing use in multiple industrial sectors:

Petrochemical Equipment:

Reactors, cracking units, exhaust systems, and pipeline networks benefit from the board’s ability to resist thermal shock and corrosive gas exposure.

Metallurgical Furnaces:

The material is applied as back-up insulation in steel ladles, tundishes, reheating furnaces, and continuous casting equipment where thermal stability directly affects operational safety.

Power Generation:

Boiler walls, turbine insulation systems, and flue gas ducts utilize calcium silicate board to improve heat retention and reduce external shell temperatures.

Cement and Glass Manufacturing:

Preheaters, kiln shells, and hot-end processing zones rely on the rigid insulation layer provided by calcium silicate board.

A Key Material in Modern Green Construction

Beyond heavy industry, the calcium silicate board has become an increasingly popular component in environmentally oriented architectural design. Its non-combustible nature, moisture resistance, and long service life make it an ideal option for:

Partition walls in commercial buildings

Fire-rated ceilings and HVAC fire barriers

Exterior wall systems in high-rise structures

Ventilation duct fireproofing

Acoustic and thermal improvement panels

Because the calcium silicate board contains no asbestos, halogens, or harmful emissions, it supports sustainable building standards and aligns with global efforts to reduce environmental impact.

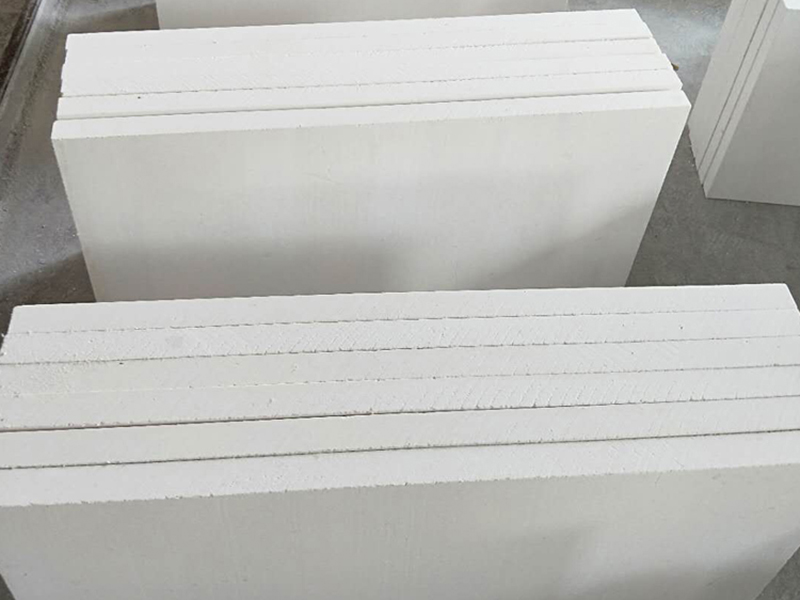

Consistency and Precision in Manufacturing

Modern production lines have allowed manufacturers to produce calcium silicate board with high dimensional accuracy and smooth surfaces, making it easy to cut, drill, and install. The material can be layered, bolted, framed, or integrated with steel structures depending on project requirements.

The board’s durability also reduces maintenance frequency, lowering long-term operational and construction costs.

A Material That Continues to Evolve

With advancements in energy efficiency and safety regulations, demand for calcium silicate board continues to rise. New formulations—such as reinforced boards, hydrophobic coatings, and lightweight variants—are being developed to meet specialized conditions in industrial and architectural sectors.

As industries move toward higher performance standards and greener building practices, calcium silicate board remains at the center of this transition, offering a dependable combination of thermal performance, structural reliability, and environmental safety.

Inquiry Now

Please leave your e-mail and we will contact you as soon as possible

contact us

Your satisfaction is our top priority. Whether you have questions, need support, or want to share feedback, our dedicated team is ready to assist you every step of the way.