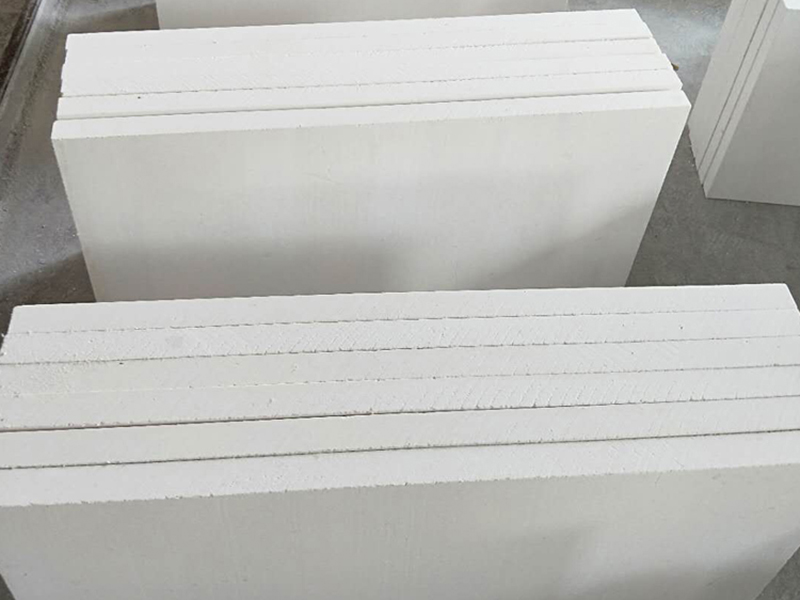

Calcium Silicate Insulation Board: The Reliable Thermal Barrier for Industrial Efficiency

In modern high-temperature industries, energy efficiency and equipment protection are key to maintaining productivity and safety. Among the most effective insulation materials available today, the calcium silicate insulation board stands out for its superior thermal performance, mechanical strength, and long-term durability. Designed for continuous use in demanding environments, this material has become a preferred solution for thermal insulation in furnaces, boilers, kilns, and power plants worldwide.

Material Composition and Characteristics

The calcium silicate insulation board is composed mainly of silica (SiO₂) and lime (CaO), reinforced with lightweight fibers. Through a controlled reaction and high-pressure autoclaving process, it forms a rigid, fine, and uniform microstructure that combines low thermal conductivity with high compressive strength.

Typical features of calcium silicate insulation boards include:

Excellent Thermal Insulation: With a thermal conductivity as low as 0.035–0.06 W/m·K, it minimizes heat loss even at temperatures up to 1000°C.

High Strength and Rigidity: Unlike many soft insulation materials, it maintains structural integrity under mechanical load and thermal stress.

Moisture and Chemical Resistance: Stable in humid environments, it resists mold growth and chemical corrosion, making it suitable for both industrial and architectural applications.

Asbestos-Free & Environmentally Safe: Modern calcium silicate insulation boards are 100% asbestos-free, meeting global environmental and safety standards.

Key Advantages

Superior Energy Efficiency: The board’s dense, uniform composition reduces heat transfer, leading to significant energy savings and improved furnace or boiler performance.

Dimensional Stability: It retains its shape and strength even under continuous thermal cycling, ensuring long service life and reduced maintenance needs.

Ease of Installation: Calcium silicate insulation board can be cut, drilled, and shaped easily using standard tools, enabling quick installation and versatile design flexibility.

Safety and Clean Operation: With no dust release or fiber irritation, it offers a clean, safe solution for industrial insulation systems.

Fire Resistance: Rated as a non-combustible material (Class A1), it provides excellent fire protection for industrial and building insulation.

Industrial Applications

The calcium silicate insulation board is used extensively across various industries for both hot and cold insulation systems. Common applications include:

Steel and Metallurgy: Lining for reheating furnaces, ladles, and tundishes where thermal shock and energy conservation are critical.

Power Generation: Insulation of boilers, turbines, exhaust ducts, and heat exchangers to minimize energy loss and enhance thermal efficiency.

Petrochemical and Refinery Plants: Protection of piping systems, reformers, and reactors against heat transfer and condensation.

Cement and Glass Industries: Used as backup insulation behind refractory linings in kilns and furnaces.

Construction and Fireproofing: Fireproof partition walls, ceilings, and structural insulation where lightweight and non-combustible materials are required.

Performance in Harsh Conditions

In high-temperature environments, calcium silicate insulation board provides stable, long-term protection that traditional mineral wool or ceramic fiber products cannot match. Its rigid structure prevents sagging or powdering, even after years of thermal exposure. The board’s surface can also be coated or laminated for enhanced moisture resistance or mechanical protection when required.

Sustainability and Longevity

Energy conservation is not just a performance factor—it’s a sustainability priority. By using calcium silicate insulation board, industries reduce fuel consumption and carbon emissions, supporting green manufacturing goals. Its durability minimizes replacement frequency, further reducing waste and lifecycle costs.

In short, calcium silicate insulation board has become an essential part of modern thermal systems—delivering reliable insulation, structural strength, and environmental safety. Whether applied in a power station, petrochemical facility, or construction project, it ensures consistent performance and long-term energy efficiency, making it a cornerstone of industrial insulation technology.

Inquiry Now

Please leave your e-mail and we will contact you as soon as possible

contact us

Your satisfaction is our top priority. Whether you have questions, need support, or want to share feedback, our dedicated team is ready to assist you every step of the way.